In the ever-evolving landscape of manufacturing, efficiency stands as a crucial pillar driving success and innovation. Among the myriad of techniques available, Steel Investment Casting has emerged as a game-changer, streamlining production processes while delivering unparalleled precision and quality. This advanced method not only allows for complex geometries and intricate designs but also reduces material waste and energy consumption, addressing the pressing need for sustainable manufacturing solutions. As industries strive to enhance their operational workflows, understanding the transformative impact of Steel Investment Casting is essential. In this blog, we will explore seven compelling reasons why this innovative casting technique is revolutionizing manufacturing efficiency, highlighting its significant benefits and showcasing its practical applications across various sectors.

Steel investment casting has emerged as a game-changer in manufacturing, particularly due to its cost-effectiveness in production. According to a report from the Steel Casting Research and Trade Association, the use of steel investment casting can reduce manufacturing costs by up to 30% compared to traditional manufacturing methods. This significant savings can be attributed to the reduction in material waste and the ability to produce complex geometries that require fewer parts and assembly processes.

Moreover, industry analysts note that the precision achieved with steel investment casting leads to lower labor costs and shorter lead times. A study by the National Institute of Standards and Technology indicates that precision casting processes can improve production efficiency by reducing machining time by approximately 50%. This not only streamlines the manufacturing workflow but also enhances overall product quality. As manufacturers increasingly seek ways to optimize cost and efficiency, the advantages of steel investment casting become increasingly evident in today's competitive market.

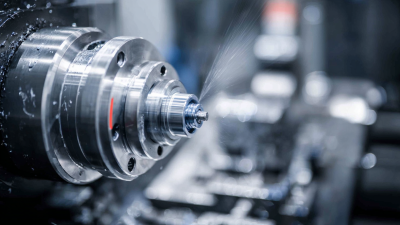

Steel investment casting has emerged as a transformative technique in modern manufacturing, significantly enhancing design flexibility for a wide range of applications. Unlike traditional casting methods, steel investment casting allows for intricate designs with complex geometries that were previously difficult or impossible to achieve. This process enables manufacturers to explore innovative shapes and features, which can lead to more efficient assembly and improved functionality in end products.

One of the key advantages of this method is the ability to create thin-walled components that provide strength without excess weight. This is particularly beneficial in industries such as aerospace and automotive, where every ounce counts. Furthermore, the precision and repeatability of steel investment casting minimize the need for extensive machining, resulting in shorter lead times and reduced material waste.

Manufacturers can adapt quickly to changes in design specifications or market demands, fostering a culture of innovation and responsiveness in their production processes. As a result, this technique is not only revolutionizing manufacturing efficiency but also paving the way for a new era of design possibilities.

Steel investment casting has emerged as a game-changer in manufacturing, particularly due to its ability to enhance surface finish. Aesthetic appeal is increasingly vital in various industries, from automotive to consumer goods. Data from a 2022 report by the Investment Casting Institute revealed that components produced through investment casting exhibit a surface roughness of as low as Ra 1.6 μm, compared to traditional methods which can have roughness values above Ra 3.2 μm. This improved surface quality not only elevates the visual appeal of components but also enhances performance by reducing friction and wear.

In addition to superior aesthetics, the finer surface finish achieved through steel investment casting minimizes the need for secondary machining processes. According to a study published in the Journal of Manufacturing Processes, companies utilizing investment casting reported a reduction in surface preparation work by up to 40%, significantly lowering production time and costs. This efficiency is a crucial factor for manufacturers striving for sustainability and shorter lead times. As industries continue to prioritize quality and efficiency, the investment in steel components with a refined surface finish will become increasingly critical in maintaining competitiveness.

Steel investment casting is reshaping the landscape of manufacturing by significantly enhancing production times through advanced casting processes. Unlike traditional casting methods, investment casting utilizes a precise mold-making technique that enables the creation of complex geometries and intricate designs. This precision reduces the need for extensive machining after casting, allowing manufacturers to expedite production cycles. As a result, companies can meet tight deadlines and respond more swiftly to market demands.

Moreover, these advanced casting processes not only streamline production but also optimize material usage. By minimizing waste and maximizing the efficiency of raw materials, manufacturers can achieve substantial cost savings while maintaining high-quality standards. The improved turnaround time and reduced material costs empower businesses to increase their output and elevate their competitive edge in the marketplace.

With the adoption of steel investment casting, manufacturers are experiencing a significant transformation that drives efficiency and innovation in their operations.

Steel investment casting is at the forefront of revolutionizing manufacturing efficiency, especially when it comes to sustainability. By minimizing waste through advanced techniques, investment casting not only enhances product quality but also significantly lessens the environmental impact associated with traditional manufacturing methods. Recent studies indicate that implementing these techniques can reduce embodied carbon emissions, aligning with the industry's shift towards greener practices.

Moreover, the integration of innovative technologies such as 3D printing and Artificial Intelligence is transforming production processes. For instance, a recent exploration highlighted that sustainable production, including additive manufacturing, can enhance manufacturing efficiency while promoting ecological responsibility. Techniques focused on reducing waste—such as ceramic shell waste valorization—further exemplify how the precision casting industry can adopt a circular economy mindset.

Tips: To maximize sustainability in your operations, consider adopting practices like reusing materials and transitioning to cleaner production methods. Additionally, staying informed on technological advancements in sustainable materials can provide your business with critical insights, enabling you to adapt and thrive in an evolving market.