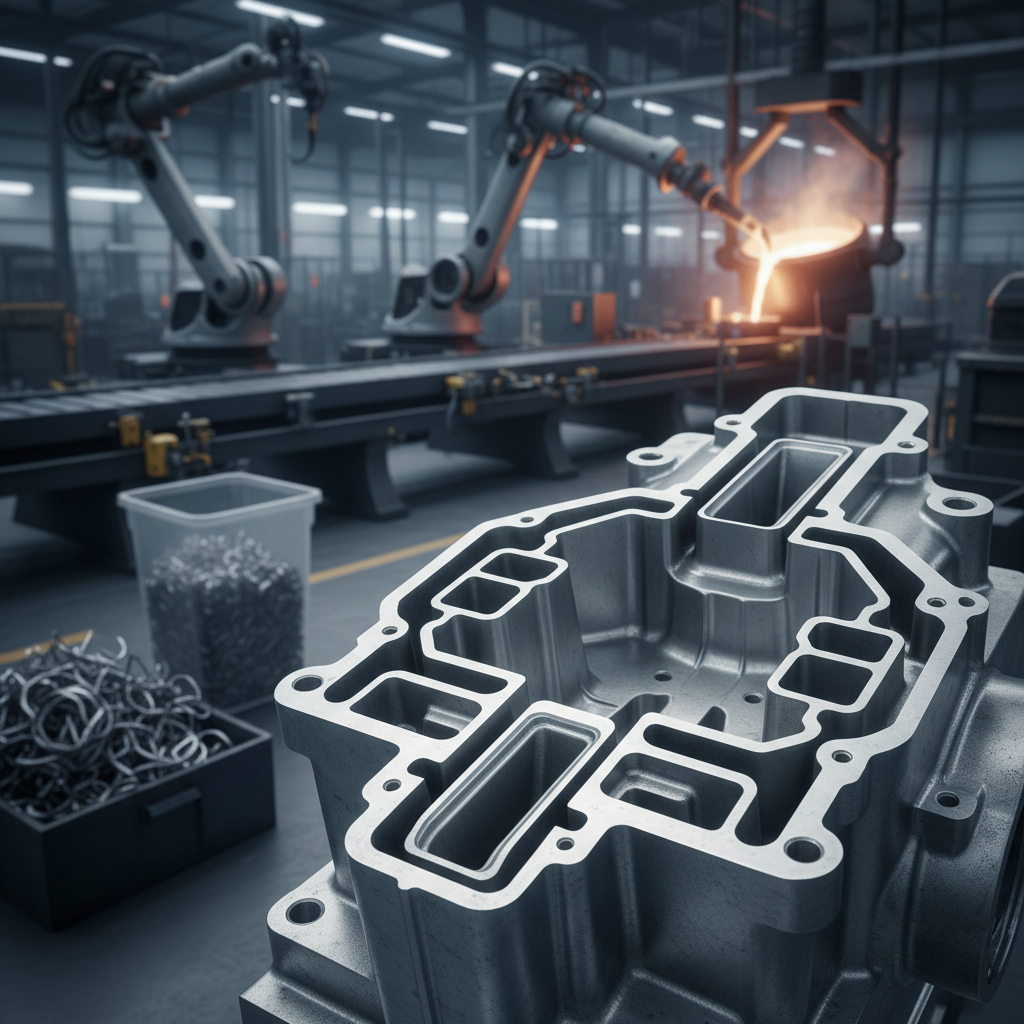

In the rapidly evolving landscape of manufacturing, precision metal casting has emerged as a pivotal process that significantly enhances the efficiency and effectiveness of production. The demand for higher tolerance in components is more pronounced than ever, as industries strive to improve their products' performance and longevity. Precision metal casting meets this demand by allowing manufacturers to create intricate designs and complex geometries with minimal tolerances, ensuring a perfect fit and optimal performance in the final product.

Moreover, the growing emphasis on sustainability in manufacturing practices has propelled the importance of reducing waste. Precision metal casting not only minimizes material loss during production but also enables the recycling of scrap materials, effectively addressing environmental concerns while maximizing resource utilization. This dual benefit of achieving higher precision and reducing waste positions precision metal casting as an essential technique for modern manufacturing, facilitating innovations across various sectors from automotive to aerospace.

As manufacturers continue to seek competitive advantages in quality and sustainability, embracing precision metal casting will undoubtedly be critical. Understanding its role in achieving elevated standards of manufacturing will empower companies to enhance their production processes, reduce costs, and contribute positively to the environment, thereby shaping the future of the industry.

Precision metal casting has emerged as a cornerstone of modern manufacturing practices, significantly contributing to achieving higher tolerances and reducing material waste. According to a report by Allied Market Research, the precision metal casting market is projected to reach $29.7 billion by 2025, highlighting its growing importance across sectors such as aerospace, automotive, and healthcare. This process not only allows manufacturers to create complex geometries with exacting specifications but also minimizes the need for extensive machining processes, which typically generate unnecessary scrap material.

Moreover, precision casting techniques, like investment casting and sand casting, have evolved to meet stringent tolerances, often within ±0.001 inches. This level of accuracy dramatically lowers the incidence of defects in cast parts, thereby enhancing product quality and reliability. Industry studies show that companies implementing precision metal casting report a reduction in production waste by up to 30%, which directly correlates with cost savings and improved sustainability efforts. As manufacturers increasingly adopt these advanced casting methods, they become more competitive and responsive to market demands, making precision metal casting an essential component of today's manufacturing landscape.

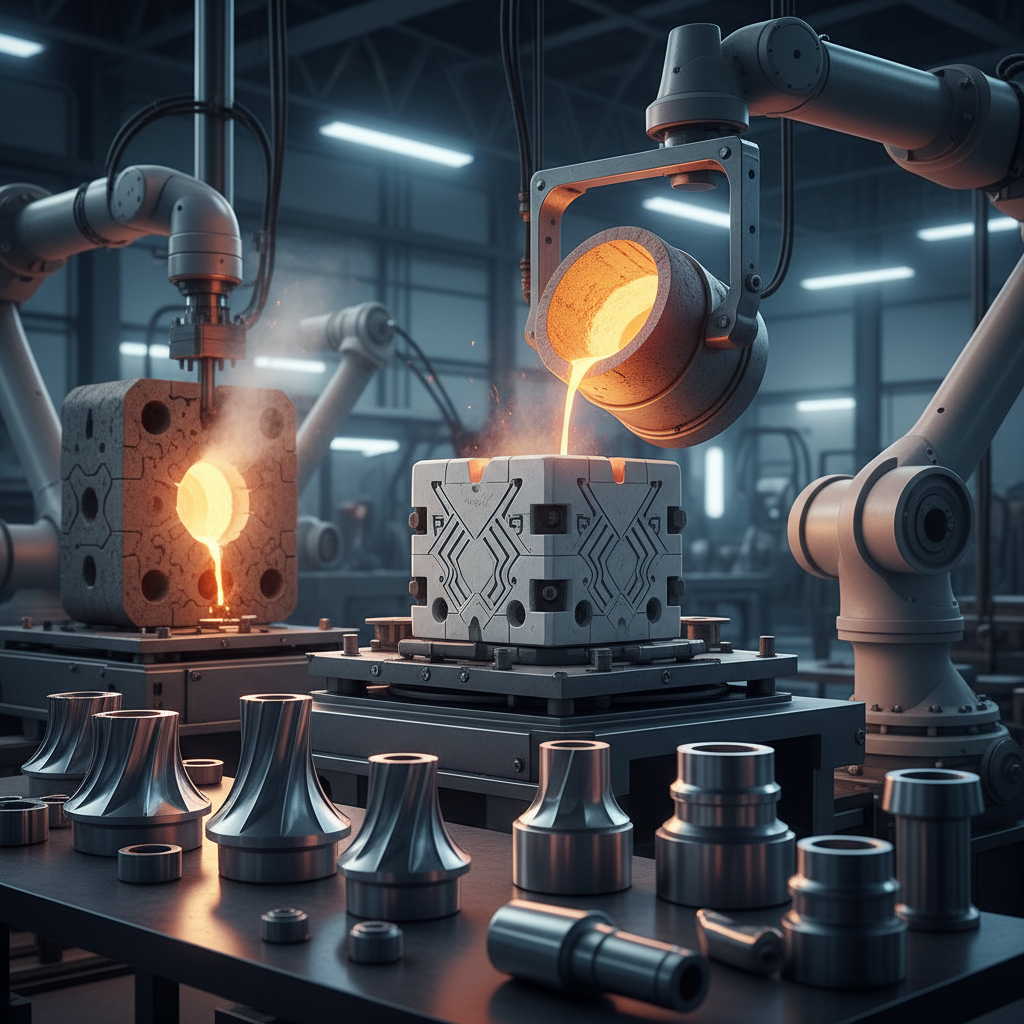

Advanced casting techniques in precision metal casting play a pivotal role in enhancing tolerance levels in manufacturing processes. With the demand for high-precision components across industries such as aerospace, automotive, and medical devices, manufacturers are increasingly adopting sophisticated methods like investment casting and lost foam casting. According to a report by Grand View Research, the global precision casting market is projected to reach USD 28.52 billion by 2025, reflecting the rising importance of high-tolerance components in various applications.

These advanced casting techniques not only improve dimensional accuracy but also reduce material waste, contributing to more sustainable manufacturing practices. For instance, a study from the North American Die Casting Association indicates that investment casting can achieve tolerances as tight as ±0.005 inches, significantly outperforming traditional machining methods. As companies strive for efficiency, the ability to produce parts with less material waste and higher precision is becoming a fundamental competitive advantage, making precision metal casting essential in today’s manufacturing landscape.

Precision metal casting plays a crucial role in modern manufacturing, particularly when it comes to minimizing material waste and enhancing environmental sustainability. By allowing for more accurate designs and tighter tolerances, this method significantly reduces the amount of raw material needed for production. Traditional casting methods often result in excess material that can lead to increased waste and higher costs. In contrast, precision casting optimizes the use of metals, ensuring that each piece is manufactured right the first time, thus significantly lowering the quantity of scrap produced.

Furthermore, the environmental benefits of precision casting extend beyond just reducing waste. By maximizing material efficiency, manufacturers can decrease their carbon footprint associated with material extraction, transportation, and disposal. This process not only conserves valuable resources but also lessens energy consumption and emissions typically associated with producing excess scrap. Overall, precision metal casting not only enhances efficiency in manufacturing but also aligns with a broader commitment to ecological responsibility, making it an essential practice for contemporary industries aiming to achieve sustainable production goals.

| Aspect | Precision Casting | Traditional Casting |

|---|---|---|

| Tolerance Level | ±0.1 mm | ±0.5 mm |

| Material Waste | < 5% | 15% - 30% |

| Production Time | Shorter | Longer |

| Energy Consumption | Lower | Higher |

| Recyclability of Material | High | Moderate |

Precision metal casting has emerged as a superior alternative to traditional manufacturing methods, especially in applications requiring tight tolerances and reduced material waste. Traditional methods, such as machining and forging, often involve more material removal processes, which can lead to significant waste and increased costs. In contrast, precision metal casting utilizes advanced techniques to create complex geometries that closely match design specifications, minimizing the need for post-processing and significantly lowering material expenditure.

Furthermore, the comparative precision offered by casting techniques allows manufacturers to achieve higher tolerances that are often unattainable with conventional methods. Precision casting produces components with tighter dimensional accuracy due to the improved control over the liquid metal's cooling and solidification processes. This not only enhances the performance of the final product but also reduces the likelihood of defects, ultimately streamlining production timelines. By prioritizing precision, manufacturers using metal casting can achieve a competitive edge, optimizing both their operational efficiencies and product quality.

The landscape of manufacturing is rapidly evolving, and precision metal casting is at the forefront of these changes, especially in the context of sustainable manufacturing. As industries increasingly focus on reducing their carbon footprint and waste, advanced precision metal casting techniques will play a crucial role. These methods not only allow for tighter tolerances in production, but also minimize material waste, making them an attractive option for organizations committed to sustainability.

Tip: Implementing software solutions for design simulations can greatly improve the efficiency of the casting process. This can help opt for materials and designs that reduce waste and enhance product quality.

In the future, we can expect to see an integration of innovative technologies such as 3D printing and smart manufacturing in precision metal casting. These advancements will not only streamline production processes but also facilitate the use of recycled materials, further bolstering the sustainability efforts of manufacturers. The shift towards circular economy principles will drive demand for processes that support both high-quality output and environmental responsibility.

Tip: Regular training for your workforce on new casting technologies can ensure that your team remains updated on best practices and innovations that contribute to sustainability.