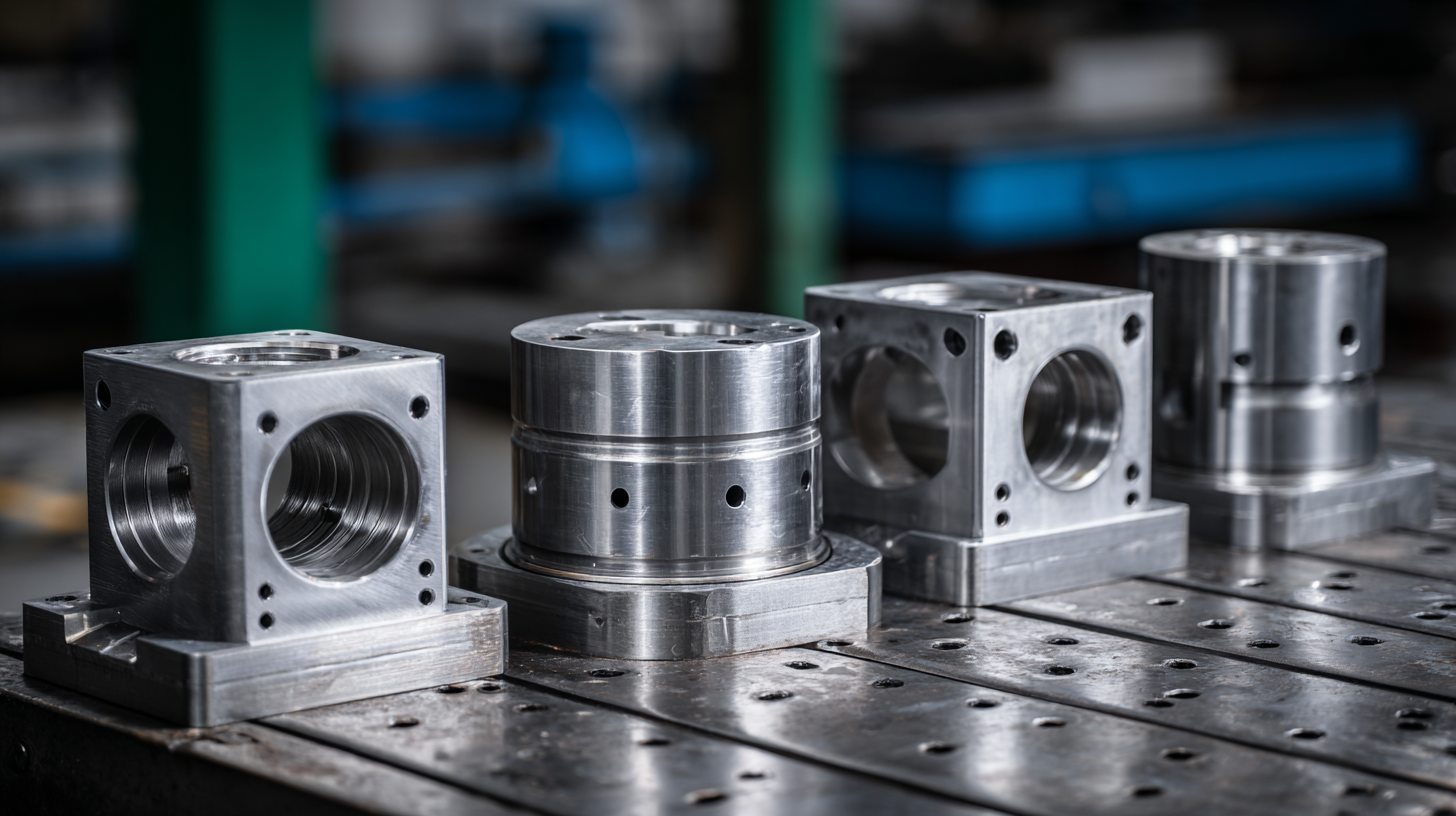

In today's manufacturing landscape, the quest for efficiency and sustainability is paramount. Precision casting has emerged as a cutting-edge solution, heralding a new era where material waste can be reduced by up to 30%, according to recent industry reports from the American Foundry Society. This advanced technique allows manufacturers to achieve intricate designs with superior dimensional accuracy while minimizing excess material through its near-net-shape capabilities. Moreover, studies indicate that precision casting not only cuts costs but also enhances the environmental footprint of manufacturing processes, aligning with the growing demand for eco-friendly practices. As industries increasingly adopt these innovative methods, understanding the intricacies and benefits of precision casting becomes essential for professionals aiming to optimize operations and contribute to sustainable manufacturing practices.

Precision casting has emerged as a transformative technique in manufacturing, particularly renowned for its ability to enhance material efficiency. According to a 2022 report by the National Institute of Standards and Technology, precision casting can reduce material waste by as much as 30% compared to traditional methods. This significant reduction stems from the technology's ability to create complex geometries with tighter tolerances, minimizing the need for additional machining and the associated scrap.

Furthermore, the precision casting process allows manufacturers to utilize high-performance alloys more effectively. A study from the American Foundry Society indicates that by employing

advanced casting techniques, companies can achieve material utilization rates exceeding 90%. This not only lowers production costs but also contributes to more sustainable practices within the industry. The impact of precision casting on material efficiency underscores its pivotal role in modern manufacturing, where every gram of material counts towards both economic and environmental goals.

Precision casting has emerged as a transformative process in manufacturing, particularly in its capacity to address material waste. According to a recent report by the American Foundry Society, traditional manufacturing techniques can result in material waste levels as high as 20-30%. However, precision casting methodology effectively reduces this waste, leading to more sustainable production practices. By allowing for highly accurate designs right from the outset, manufacturers can significantly minimize excess material usage and the associated costs.

Precision casting has emerged as a transformative process in manufacturing, particularly in its capacity to address material waste. According to a recent report by the American Foundry Society, traditional manufacturing techniques can result in material waste levels as high as 20-30%. However, precision casting methodology effectively reduces this waste, leading to more sustainable production practices. By allowing for highly accurate designs right from the outset, manufacturers can significantly minimize excess material usage and the associated costs.

The environmental impact of reduced waste in manufacturing is profound. A study published by the Journal of Cleaner Production highlights that implementing precision casting can lead to a decrease in the carbon footprint of production processes by up to 25%. This not only conserves natural resources but also lowers energy consumption typically associated with material processing and disposal. As industries strive to adhere to stricter environmental regulations and corporate social responsibility standards, the adoption of precision casting not only fulfills these requirements but positions companies as leaders in sustainable manufacturing.

Precision casting is revolutionizing the manufacturing industry by delivering significant cost savings, as highlighted in a recent report by MarketsandMarkets, which states that the precision casting market is projected to grow from USD 19.8 billion in 2022 to USD 29.5 billion by 2027, at a CAGR of 8.1%. This increased adoption stems from the process's ability to minimize material waste, with studies showing reductions of up to 30% in wastage compared to traditional casting methods.

From a financial perspective, the shift to precision casting not only reduces raw material costs but also enhances overall operational efficiency. According to a study by Technavio, industries that implement precision casting techniques can expect a return on investment (ROI) ranging from 10% to 20% in the first year alone. Such financial benefits are further amplified when considering reduced labor costs and lower energy consumption associated with precision casting processes. As manufacturers increasingly strive for sustainability alongside profitability, precision casting emerges as a compelling solution that redefines efficiency and cost-effectiveness in production.

Precision casting has emerged as a game-changing technique in the manufacturing sector, especially when compared to traditional methods like sand casting or forging. Traditional casting techniques often produce significant amounts of scrap material due to the larger tolerances and need for additional machining. In contrast, precision casting allows for tighter tolerances and a near-net shape production, which significantly reduces excess material. This improvement can lead to a material waste reduction of up to 30%, making it not only an environmentally friendly option but also a cost-effective solution for manufacturers.

When considering a shift to precision casting, it's essential to evaluate your production needs. Invest time in selecting a reputable foundry that specializes in precision casting to ensure high-quality output. Additionally, make sure to leverage advanced software for design and simulation to optimize the casting process further and reduce potential waste.

Moreover, maintaining open communication with your suppliers about specifications and requirements can lead to better collaboration and ultimately lower overall costs. Regularly reviewing and analyzing the production outcomes will help you fine-tune processes, ensuring that your shift to precision casting is as efficient as possible.

Precision casting technology is at the forefront of revolutionizing manufacturing processes. By enabling manufacturers to produce highly accurate components, this innovative approach significantly reduces material waste, with potential savings of up to 30%. As industries seek ways to increase efficiency while minimizing their environmental footprint, precision casting has emerged as a sustainable solution that not only conserves resources but also enhances overall productivity.

In the context of the global casting and forging market, projected to grow from USD 187.38 billion in 2025 to USD 260 billion by 2033, the demand for advanced techniques like precision casting is on the rise. Countries that are successfully scaling their manufacturing capabilities are increasingly adopting such innovations. The integration of digital technologies with traditional methods is transforming operations, enabling manufacturers to adapt to evolving market needs.

**Tips:**

- Embrace additive manufacturing frameworks to complement precision casting, enhancing efficiency further.

- Continually monitor market trends to identify the latest advancements in technology that could optimize your production processes.

- Foster a culture of innovation within your organization to stay ahead in the competitive manufacturing landscape.

| Casting Method | Material Waste Reduction (%) | Cost Savings per Unit ($) | Production Time (hours) |

|---|---|---|---|

| Investment Casting | 25% | 5.00 | 12 |

| Die Casting | 30% | 3.50 | 10 |

| Sand Casting | 15% | 2.00 | 15 |

| Investment Die Casting | 20% | 4.00 | 13 |

| Lost Foam Casting | 28% | 4.50 | 11 |