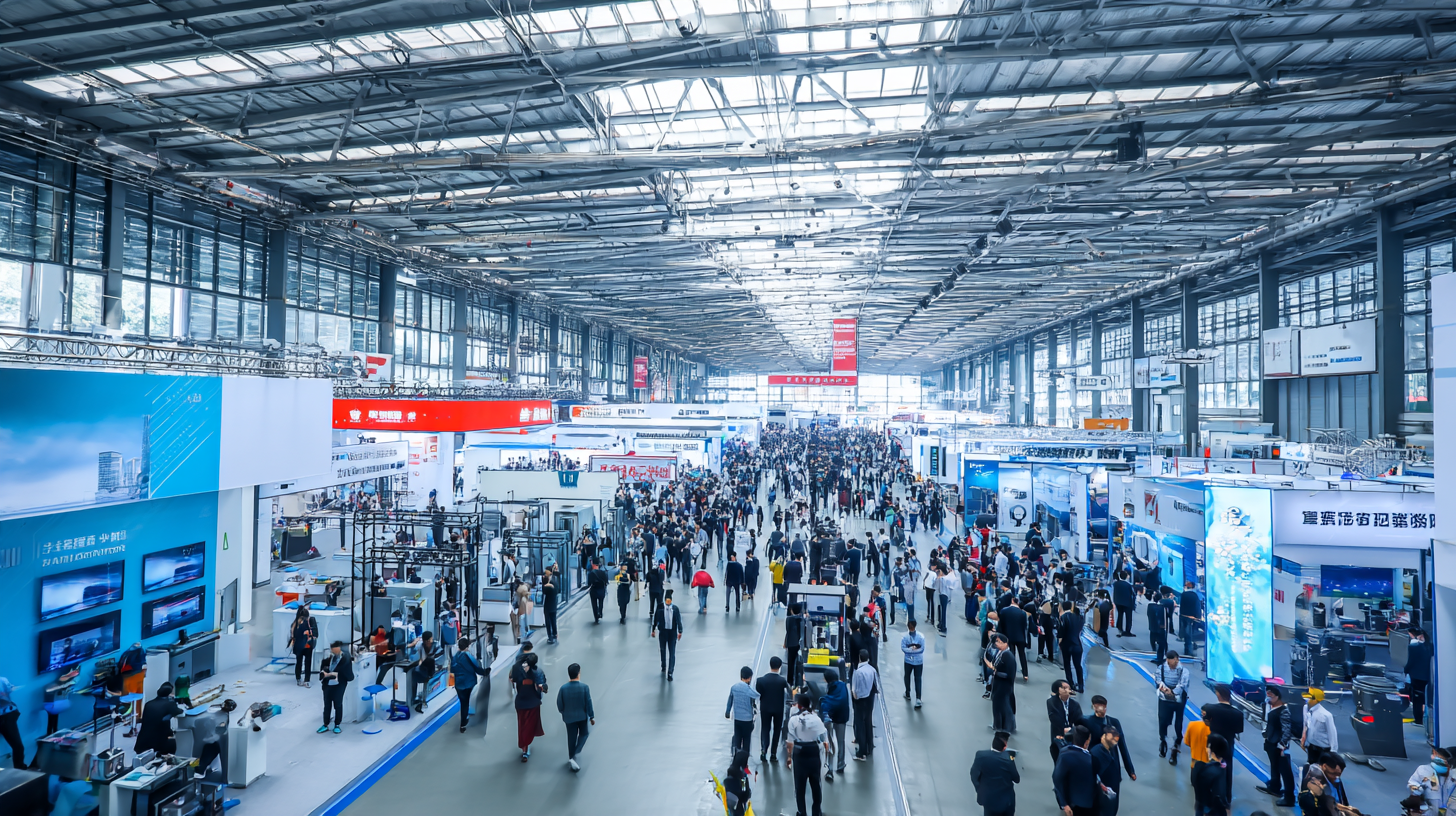

The 138th China Import and Export Fair in 2025 presents a critical platform for the showcase of innovations in the manufacturing sector, particularly in Lost Wax Investment Casting. This advanced technique, renowned for its ability to produce precise and intricate designs, is increasingly gaining traction across various industries, including aerospace, automotive, and medical devices. According to the Global Lost Wax Investment Casting Market Report, the market size is projected to reach USD 11.14 billion by 2030, growing at a CAGR of 6.5% from 2022 to 2030, driven by the demand for high-quality components with complex geometries. As manufacturers continue to adopt more sustainable practices and advanced materials, the innovations highlighted at the Fair are expected to play a pivotal role in shaping the future landscape of Lost Wax Investment Casting. With a focus on cutting-edge technology and process optimization, this event will undoubtedly facilitate knowledge exchange and foster collaboration among industry leaders.

The 138th China Import and Export Fair in 2025 presents a critical platform for the showcase of innovations in the manufacturing sector, particularly in Lost Wax Investment Casting. This advanced technique, renowned for its ability to produce precise and intricate designs, is increasingly gaining traction across various industries, including aerospace, automotive, and medical devices. According to the Global Lost Wax Investment Casting Market Report, the market size is projected to reach USD 11.14 billion by 2030, growing at a CAGR of 6.5% from 2022 to 2030, driven by the demand for high-quality components with complex geometries. As manufacturers continue to adopt more sustainable practices and advanced materials, the innovations highlighted at the Fair are expected to play a pivotal role in shaping the future landscape of Lost Wax Investment Casting. With a focus on cutting-edge technology and process optimization, this event will undoubtedly facilitate knowledge exchange and foster collaboration among industry leaders.

The 138th China Import and Export Fair in 2025 will serve as a pivotal platform for showcasing innovative techniques in lost wax investment casting. This time-honored method, increasingly favored in various industries from aerospace to jewelry, has evolved significantly, reflecting advancements in technology and materials. According to a recent report by Mordor Intelligence, the global investment casting market is projected to reach USD 25 billion by 2026, growing at a CAGR of around 5% from 2021 to 2026. This growth is largely attributed to the rising demand for high-precision cast parts and the increasing adoption of advanced manufacturing technologies.

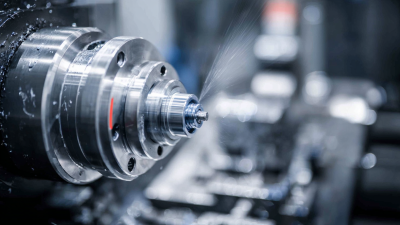

At the fair, attendees will be introduced to cutting-edge innovations such as 3D printing of wax patterns, which significantly reduce production time and costs while enhancing design flexibility. A study from Grand View Research highlights that the integration of 3D printing in investment casting could potentially improve production efficiency by over 30%. Furthermore, advancements in materials science have led to the development of new alloys that offer improved mechanical properties and corrosion resistance, making them ideal for critical applications. As industry leaders and researchers gather to share their insights, the fair promises to ignite discussions on the future of lost wax investment casting and its role in evolving manufacturing landscapes.

The lost wax investment casting industry is poised for significant growth in 2025, driven by increasing demand across various sectors, particularly the automotive industry. Recent projections indicate that the market for iron castings alone is expected to expand by USD 50.34 billion from 2024 to 2028, underlining the versatility and importance of casting techniques in manufacturing resilient and complex components. As the industry adapts to modern technologies, including advancements in artificial intelligence, efficiency and precision in production processes are set to improve, further fueling market expansion.

At the same time, the global die casting market is on track to reach a value of USD 112.14 billion by 2029, reflecting a robust growth trajectory influenced by innovation and market diversification. As manufacturers showcase their latest innovations at events such as the 138th China Import and Export Fair, the emphasis will be on harnessing cutting-edge technologies to enhance operational capabilities. This synergistic growth across sectors signifies a vibrant landscape for investment casting, driving both industry players and investors to seek opportunities amid evolving market dynamics.

The 138th China Import and Export Fair in 2025 will showcase groundbreaking innovations in the lost wax investment casting process, with a strong emphasis on sustainability. The industry is increasingly focused on reducing waste and minimizing energy consumption, reflecting a broader trend toward eco-friendly manufacturing practices. By adopting advanced technologies and materials, companies are not only enhancing production efficiency but also lowering their environmental footprint.

Tips for achieving sustainable investment casting include selecting recyclable materials and optimizing mold designs to reduce waste. Utilizing energy-efficient furnaces can also significantly decrease overall energy consumption during the casting process. Furthermore, implementing closed-loop systems for waste material can allow for the repurposing of scrap metal, promoting a circular economy within the industry.

Innovations such as 3D printing of wax patterns and the use of alternative energy sources are transforming the investment casting landscape. These advancements not only streamline production but also align with global sustainability goals, paving the way for a more responsible future in metalworking. By prioritizing eco-friendly practices, the industry can meet the demands of environmentally conscious consumers and regulators alike.

The 138th China Import and Export Fair in 2025 serves as a pivotal platform for showcasing innovations in lost wax investment casting, a technique that has been refined over centuries. Central to this evolution is the integration of advanced materials that significantly enhance product performance and longevity. By adopting state-of-the-art alloys and composites, manufacturers can produce components that not only withstand the rigors of demanding applications but also exhibit improved resistance to wear and corrosion.

Highly engineered materials, such as nickel-base superalloys and ceramic composites, are at the forefront of this innovation. These materials facilitate the production of intricate geometries with superior mechanical properties, allowing for more robust designs in industries ranging from aerospace to medical devices. The advancements in material science, combined with cutting-edge casting technology, are transforming lost wax investment casting into a cornerstone of modern manufacturing, ensuring parts maintain their integrity under extreme conditions while extending their functional lifespan.

By 2025, China is positioned to enhance its competitiveness in the lost wax investment casting market, a field that blends traditional craftsmanship with cutting-edge technology. As leading manufacturers across the globe increasingly seek precision and efficiency, China's robust supply chain and skilled workforce create a unique advantage. The country has invested heavily in research and development, enabling innovation in materials and processes that improve casting quality and reduce waste. This strategic focus not only allows Chinese firms to meet international standards but also supports sustainability initiatives that resonate with global buyers.

Furthermore, the dynamics of international trade at events like the 138th China Import and Export Fair will showcase China's advancements in lost wax investment casting. Manufacturers will have the opportunity to display their latest innovations, forging partnerships and capturing the interest of buyers from diverse sectors, including aerospace, automotive, and medical devices. With an emphasis on adapting to market trends and technological advancements, China's role will not only cement its position in the global market but also stimulate further growth and collaboration within the industry.