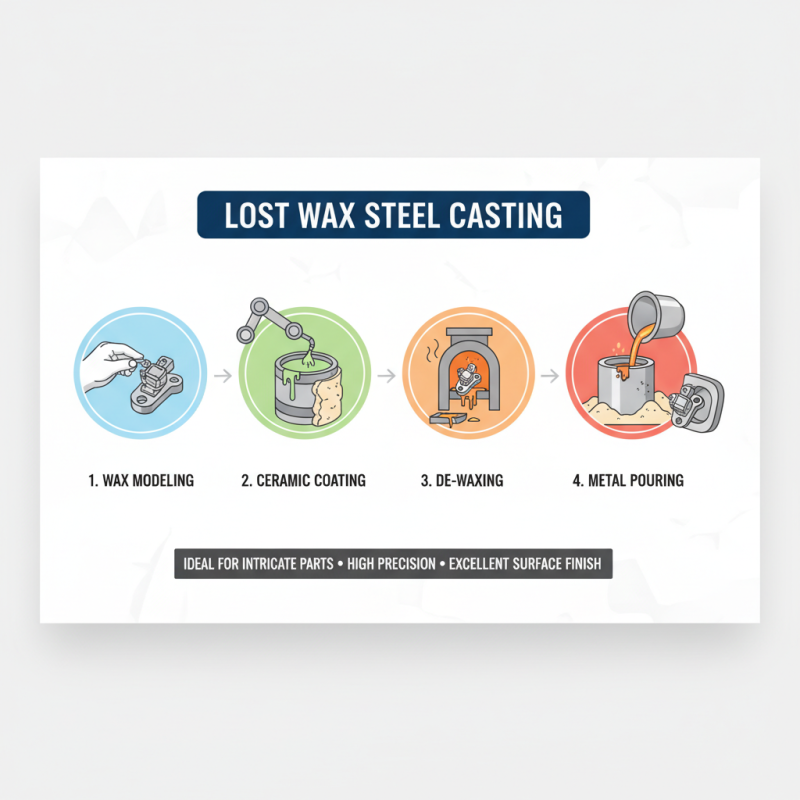

Lost Wax Steel Casting is a time-honored technique that has stood the test of time, celebrated for its ability to create intricate and highly detailed metal components. This method, also known as investment casting, involves the creation of a wax model which is then encased in a ceramic shell. Once the shell is formed, the wax is melted away, and molten steel is poured into the cavity, resulting in highly precise and durable castings. As industries continue to evolve, so too do the practices surrounding Lost Wax Steel Casting, making it crucial for professionals to stay informed about the best practices that can enhance efficiency, quality, and safety.

In this article, we will explore the ten best practices for Lost Wax Steel Casting that every foundry worker, engineer, and designer should know. From optimizing wax patterns to selecting the right materials and controlling temperature, these insights can help you avoid common pitfalls and achieve the best results in your casting projects. Whether you are a seasoned expert or just starting in this field, understanding these best practices is essential for ensuring high-quality outcomes and maximizing the benefits of Lost Wax Steel Casting in various applications.

The lost wax steel casting process, also known as investment casting, is a time-honored technique that is ideal for producing intricate and detailed metal parts. In this method, a wax model is created and coated with a ceramic material to form a mold. Once the mold hardens, the wax is melted away, leaving a cavity in the shape of the desired part. Molten steel is then poured into this cavity, allowing for high precision and excellent surface finish.

One of the key benefits of the lost wax process is its ability to create complex geometries that are often impossible to achieve with traditional casting methods. This makes it especially useful in industries such as aerospace and automotive, where component designs are intricate and demanding. A tip for beginners is to pay close attention to the waxing process; ensuring that the wax model is flawless will drastically improve the quality of the final cast.

Another important practice is to carefully control the temperature at each stage. For instance, preheating the mold before pouring can reduce the chances of defects. Additionally, using a vacuum system during pouring can help eliminate air pockets. Beginners should ensure that they are familiar with the various parameters of the process, as adjustments can lead to significantly better results in the final product.

Lost wax steel casting, an age-old technique, involves several key materials and tools that are critical for successful implementation. The primary material in this process is the steel itself, which must be selected based on the specific properties required for the final product. Common steel alloys used in lost wax casting include stainless steel and carbon steel, chosen for their durability and resistance to wear. According to the American Foundry Society, steel casting accounted for over 770,000 tons in production in the United States in 2022, reflecting the growing demand in various industries, including automotive and aerospace.

In addition to steel, other essential materials include wax for creating the initial model, ceramic for making the investment mold, and refractory materials that withstand high-temperature exposure during the casting process. The tools required for lost wax steel casting encompass heating equipment, such as induction furnaces for melting steel, and casting machines for the precise pouring of molten metal. A report from the Casting Industry Suppliers Association highlights that advancements in 3D printing technologies are transforming the material preparation landscape, allowing for more intricate wax models to be produced with greater efficiency. Integrating these tools and materials effectively enables practitioners to produce components with intricate details and high structural integrity, essential in meeting the exacting standards of modern engineering applications.

| Practice | Description | Key Materials | Tools Required |

|---|---|---|---|

| Pattern Creation | Create accurate and detailed patterns for molding. | Wax or resin | CNC machine, 3D printer |

| Shell Building | Build a robust shell around the pattern. | Ceramic materials, silica sand | Mixing tools, pouring equipment |

| Wax Removal | Melt and drain the wax from the shell. | Not applicable | Furnace, hot air blower |

| Mold Firing | Strengthen the mold by firing it at high temperatures. | None | Kiln, temperature gauges |

| Metal Pouring | Pour molten metal into the mold. | Steel alloy | Crucible, pouring ladle |

| Cooling | Allow the metal to cool and harden. | None | Cooling racks |

| Shell Removal | Break the ceramic shell to reveal cast part. | None | Chisel, hammer |

| Surface Finishing | Clean and finish the surface of the cast part. | Abrasives | Grinders, sanders |

| Quality Inspection | Inspect cast parts for defects and tolerances. | Measuring tools | Calipers, gauges |

| Final Assembly | Assemble components if necessary. | Fasteners | Hand tools |

Creating a wax model for lost wax steel casting is a meticulous yet rewarding process that forms the basis of high-quality metal objects. The first step involves constructing a detailed original model, typically using materials like clay or plasticine. This model serves as a reference for your wax counterpart, so it's crucial to pay attention to fine details, including contours and textures. Once the original model is complete, the next phase is to create a mold that captures its precise geometry. This can be done using a silicone or rubber material that can withstand the heat and allow for easy removal of the wax once set.

After preparing the mold, the next step is to fill it with molten wax, a technique that requires careful temperature control to avoid bubbles or imperfections. Pour the wax slowly and ensure that it fills every detail of the mold. Once cooled, the wax model will need to be carefully removed from the mold. It's essential to check for any defects at this stage, as they will translate to the final metal piece. The last part of the process involves adding a gating system, which helps in the flow of metal during the casting. Following these steps diligently ensures that your wax model is ready for the casting process, laying the foundation for creating intricate and high-quality steel objects.

This chart illustrates the efficiency of lost wax steel casting across different stages. The data represents the average time (in hours) taken for each key step in the process.

When it comes to successful lost wax steel casting, mastering investment and mold preparation techniques is crucial. The investment material, typically a mixture of silica and binder, must be selected carefully to ensure it can withstand the heat during the metal pouring process. A uniform consistency in the investment mix is vital, as irregularities can lead to defects in the final casting. Achieving the right thickness in the mold can also significantly affect the casting's strength and surface finish.

Tips: Always preheat the molds to enhance the bonding with the investment material, which aids in achieving a smoother surface. Additionally, employing a vacuum process during mold making can help eliminate air bubbles, preventing weak spots that may compromise the integrity of the steel cast.

Furthermore, meticulous attention to detail during the drying phase is important. Allow the investment to cure fully, ensuring no moisture is trapped that could lead to steam explosions when molten metal is poured. Regularly inspect the molds for any signs of cracks or imperfections before usage, as these can lead to costly mistakes in the production cycle.

Tips: Implementing a controlled environment for mold curing can minimize issues related to humidity and temperature fluctuations, resulting in a more reliable casting process.

Lost wax casting, also known as investment casting, presents several challenges that can significantly impact product quality. One common issue is the dimensional accuracy of the cast part. According to a report by the American Foundry Society, tolerance discrepancies can reach up to ±0.005 inches for intricate geometries. This often results from thermal expansion, shrinkage during cooling, and misalignment of the wax pattern during mold assembly.

To overcome these challenges, it is essential to implement precise control measures during the wax pattern production process and to consider the thermal properties of the materials used for the mold and core.

Another significant challenge is the presence of defects such as porosity or inclusions. A survey conducted by the Investment Casting Institute found that nearly 40% of defects in lost wax castings can be traced back to improper wax pouring techniques or inadequate venting.

To minimize such defects, it is crucial to adopt best practices in wax pattern design, including optimizing gate and riser placements and ensuring sufficient venting paths to facilitate the escape of gas during pouring. Implementing a robust quality control system can also help in detecting and rectifying defects early in the casting process, thereby improving overall yield and reducing waste.