Stainless Steel Castings are essential in various manufacturing sectors. According to a recent report by MarketsandMarkets, the global market for stainless steel castings is expected to reach $7.3 billion by 2025, driven by increased demand across industries. This material provides excellent corrosion resistance and durability, making it a popular choice in environments where harsh conditions prevail.

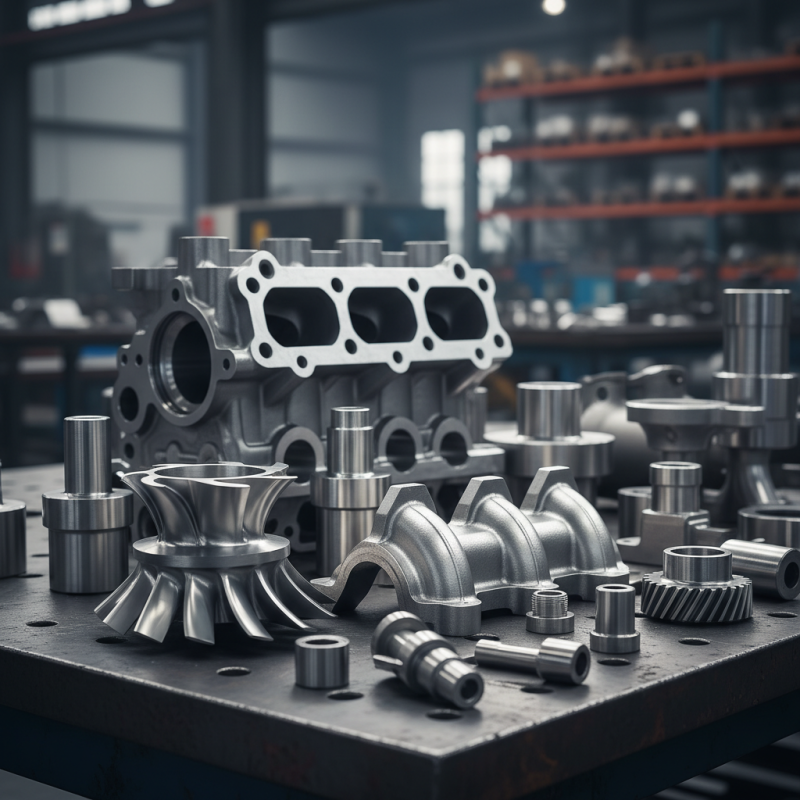

Many manufacturers rely heavily on stainless steel castings for critical components. For example, in the aerospace industry, these castings serve vital roles in engine parts and structural components. Similarly, in the automotive sector, they are used in exhaust systems and engine blocks. However, the rising costs of raw materials can pose a challenge, complicating production processes.

Despite their benefits, not all stainless steel castings are created equal. Some products may fall short in performance or finish. This inconsistency necessitates rigorous quality checks to ensure reliability. As the industry grows, manufacturers must address these imperfections to fully leverage the advantages that stainless steel castings offer.

Stainless steel castings play a vital role in various manufacturing sectors. They are widely used in the automotive industry. Components like engine parts and transmission cases benefit from stainless steel's strength and resistance to corrosion. These properties help ensure longevity under harsh conditions.

In the aerospace sector, stainless steel castings are crucial. They are employed in structural components and engine parts. The durability of stainless steel is essential to meet safety protocols. However, the cost of stainless steel can sometimes hinder its adoption. Companies must weigh the benefits against the expenses involved.

Tips: Always consider whether the application justifies the material choice. Stainless steel might not be necessary for every project. Additionally, evaluate potential failures in design and production. This evaluation can prevent costly mistakes later.

Another notable application of stainless steel castings is in the medical field. Equipment like surgical tools requires high standards of hygiene. Stainless steel fulfills this need effectively. However, manufacturers must ensure that castings are free from imperfections. Such flaws can lead to serious health risks. Regular quality checks are essential.

| Application | Industry | Benefits |

|---|---|---|

| Medical Equipment | Healthcare | Corrosion resistance, hygiene |

| Food Processing Parts | Food Industry | Non-reactive, easy to clean |

| Marine Applications | Marine | Durability, resistance to saltwater |

| Automotive Components | Automotive | Strength, lightweight |

| Architectural Elements | Construction | Aesthetic appeal, weather resistance |

| Oil and Gas Equipment | Energy | High resistance to extreme temperatures |

| Chemical Processing Components | Chemicals | Corrosion resistance, durability |

| Aerospace Parts | Aerospace | Lightweight, high strength |

| Mining Equipment | Mining | Durability, wear resistance |

| Water Treatment Components | Environmental | Corrosion resistance, long lifespan |

Stainless steel castings offer numerous advantages in manufacturing processes. They are durable and resistant to corrosion, making them ideal for various applications. This resistance ensures longevity in products exposed to harsh environments. The ability to withstand high temperatures adds to their versatility in industries like aerospace and automotive.

One notable advantage is their intricate design capability. Casting allows for complex shapes that would be difficult to achieve with other methods. This fosters innovation in product design. However, quality control remains a challenge. Inconsistent casting can lead to defects that compromise strength. Maintaining rigorous inspection processes is crucial. Ultimately, understanding these advantages and pitfalls shapes the future of manufacturing.

Stainless steel castings are widely used in various manufacturing sectors. Their superior properties contribute significantly to casting performance. One key property is corrosion resistance. According to a recent study, stainless steel outperforms carbon steel by over 200% in terms of corrosion resistance, particularly in harsh environments.

Another important feature is durability. Stainless steel castings can withstand high temperatures and mechanical stress. This quality is crucial for industries such as aerospace and automotive, where casting failure can lead to severe consequences. A report indicates that stainless steel castings have a failure rate of less than 1% in critical components, demonstrating their reliability in demanding applications.

Despite these advantages, challenges exist. The casting process can be complex. It requires precise temperature control and skilled labor to avoid defects. Common issues include shrinkage and porosity, which can compromise strength. Manufacturers must continually review their processes to enhance quality. Addressing these concerns is vital for improving overall performance and reducing operational costs.

When comparing stainless steel castings to other materials, several factors come into play. Stainless steel is known for its excellent corrosion resistance, which is vital in manufacturing environments. According to a recent industry report, about 65% of corrosion-related failures in manufacturing can be attributed to inferior materials. This highlights the critical need for durable options like stainless steel. Unlike aluminum, which is lighter but less resistant, stainless steel maintains integrity under high temperatures and harsh conditions.

Weight is often a concern. For instance, titanium is lighter than stainless steel, but it's also significantly more expensive. A comparative analysis shows that manufacturers could save about 30% on material costs by choosing stainless steel over titanium. Furthermore, stainless steel castings are more versatile. They can be easily welded and machined, which is not always the case with other materials. However, it's essential to note the challenges associated with stainless steel, such as higher melting points that require specialized equipment for casting.

The benefits of stainless steel castings certainly shine through, but they aren't without their imperfections. Certain grades can suffer from stress corrosion cracking under specific conditions. Best practices must be followed to avoid such issues. Despite these drawbacks, the advantages often outweigh the limitations, making stainless steel a preferred choice in many manufacturing applications.

The stainless steel casting industry is evolving rapidly. Future trends indicate an increased focus on sustainability. Many manufacturers now prioritize eco-friendly practices. Research shows that up to 80% of stainless steel can be recycled. This offers a significant reduction in waste. It also helps lower production costs.

Another key trend is the use of advanced technologies. Additive manufacturing and 3D printing are becoming common. These methods enhance precision and reduce production times. A report by MarketsandMarkets predicts a growth rate of 6.5% in this sector over the next five years. However, the integration of these technologies can be challenging for traditional manufacturers. Resistance to change often hampers innovation.

Customization is on the rise too. Clients seek tailored solutions for specific needs. They want unique designs and features. This trend demands flexibility from manufacturers. Adapting to these requirements can strain resources. There’s potential for inefficiency in supply chains. Manufacturers must rethink their strategies to stay relevant.