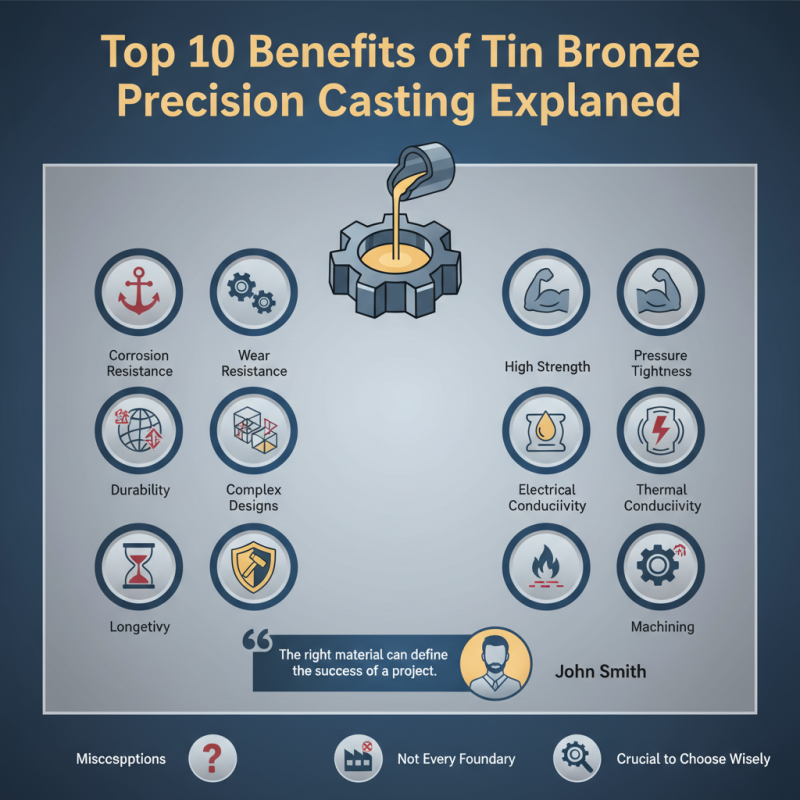

In the fascinating world of manufacturing, Tin Bronze Precision Casting plays a pivotal role. Experts often highlight its significance. John Smith, a renowned casting expert, once stated, "The right material can define the success of a project." This sentiment rings true, especially when discussing the advantages of Tin Bronze Precision Casting.

The benefits of this technique are numerous and impactful. With its superior corrosion resistance, tin bronze is perfect for marine applications. It offers excellent wear resistance, making it ideal for machinery parts. Additionally, the fluidity of tin bronze ensures detailed, precise castings that capture complex designs. These features improve durability and longevity but come with challenges.

Even seasoned professionals have room for reflection. There are still misconceptions surrounding the casting process. Not every casting house can handle tin bronze effectively. Understanding the intricacies of this specialized casting is crucial. Manufacturers must carefully choose their processes to unlock the full potential of Tin Bronze Precision Casting.

Tin bronze precision casting stands out for its unique properties and versatility. This process combines tin and copper, yielding excellent corrosion resistance and improved wear characteristics. According to a report by Research and Markets, the demand for bronze alloys is set to grow at a rate of 5% per year. This growth is primarily driven by industries that require durable materials.

Tin bronze's superb mechanical strength makes it a top choice for critical applications. It's often used in marine hardware, valves, and various industrial components. The intricate casting process allows manufacturers to produce complex shapes with high dimensional accuracy. However, there are challenges. The casting medium demands precise temperature control, and inconsistent heating can lead to imperfections. These issues require constant monitoring and adjustment during production.

Moreover, while the benefits are clear, the sustainability of materials is still a concern. The extraction of tin raises environmental questions, and alternatives are being explored. As companies focus on green initiatives, the industry may need to adapt. Striking a balance between performance and environmental responsibility remains a crucial challenge in the future of tin bronze precision casting.

Tin bronze is known for its remarkable durability and corrosion resistance. This alloy, primarily composed of copper with tin, performs well in harsh environments. According to studies from the American Foundry Society, tin bronze can endure conditions that other metals cannot.

The corrosion resistance of tin bronze is particularly impressive. It can withstand marine environments and industrial applications where moisture and chemicals are prevalent. Research shows that tin bronze has a corrosion rate significantly lower than that of standard brass. The National Institute of Standards and Technology reports that this resistance is due to the formation of a protective oxide layer, which helps maintain the alloy's integrity over time.

Moreover, the strength of tin bronze is noteworthy. Its tensile strength often surpasses that of aluminum and stainless steel. This strength translates into longevity in applications, reducing the need for frequent replacements. However, some fabrication processes can impact this benefit. Improper casting techniques may lead to weaknesses or flaws. Thus, precision casting remains essential to fully realize tin bronze's potential. Finding the right balance in casting methods is crucial for maximizing the advantages of this versatile alloy.

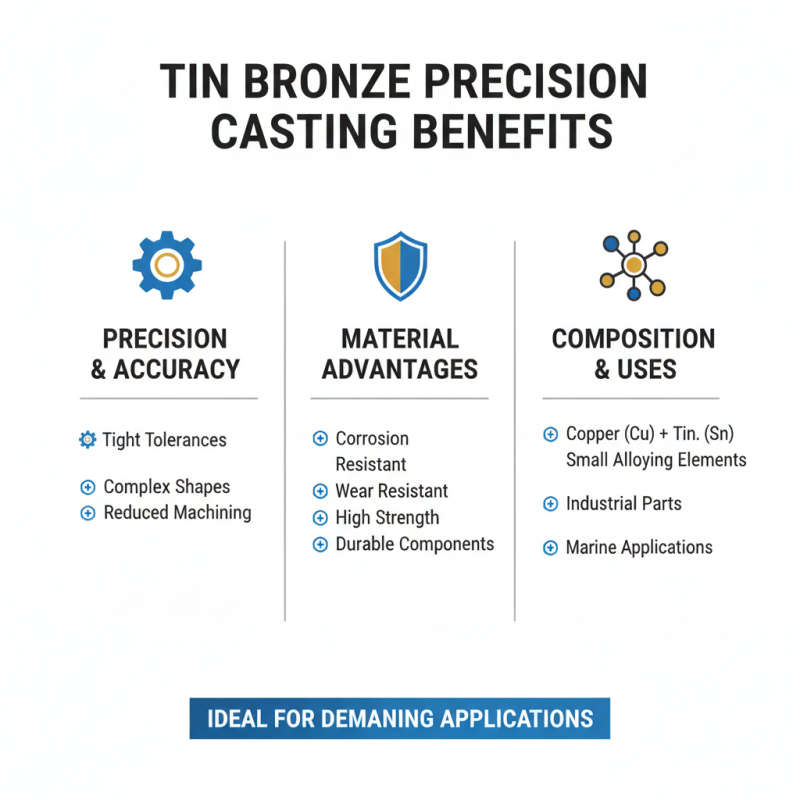

Tin bronze precision casting offers exceptional benefits in manufacturing processes, particularly in terms of precision and accuracy. The unique properties of tin bronze, such as its resistance to corrosion and wear, make it a favored material. This metal alloy consists of tin, copper, and small amounts of other elements, resulting in durable components ideal for various applications.

In precision casting, maintaining tight tolerances is essential. Tin bronze allows manufacturers to produce complex shapes with minimal waste. The liquid metal flows accurately into molds, ensuring that even intricate designs achieve a high level of detail. This is crucial in sectors such as aerospace and automotive, where literally every millimeter matters. However, achieving perfect precision can be challenging. Slight variations during the casting process can impact the final product. It requires ongoing refinement and attention to detail.

The combination of tin and bronze enhances mechanical properties, making castings resilient. These can endure harsh environments, providing longevity. Yet, not all batches of tin bronze will yield the same results. Variability in material quality can lead to inconsistent performance. Continuous testing and quality checks are vital. However, this can slow down production and add costs. Emphasizing precision in manufacturing with tin bronze leads to better outcomes, yet demands patience and diligence.

Cost-Effectiveness of Tin Bronze Casting Methods

Tin bronze precision casting offers significant cost-effectiveness over traditional metalworking methods. According to industry reports, tin bronze has a lower melting point compared to other bronze alloys. This allows for reduced energy costs during production. The casting process can yield complex shapes with high precision directly from the mold. Thus, there’s less material waste, enhancing overall cost efficiency.

Additionally, the longevity and corrosion resistance of tin bronze contribute to its cost-effectiveness. Components made from tin bronze often have a longer lifespan than those made from other materials. A study found that items made of tin bronze could last up to 50% longer, leading to lower replacement costs. It is crucial, however, to consider the upfront investment. Some businesses hesitated to switch due to initial expenses, but the long-term savings are substantial.

It's also worth noting that not all tin bronze casting techniques deliver the same results. Factors such as mold quality and production methods impact final costs. As a result, companies must evaluate their specific needs and potential returns before deciding. This reflection can lead to better financial decisions in the casting industry. Striking the right balance between cost and quality remains a crucial challenge.

Tin bronze casting has various applications across different industries. This material is known for its excellent corrosion resistance. It is ideal for marine and aerospace equipment. Tin bronze components can withstand harsh environments and reduce maintenance needs. This makes them highly valued in these sectors.

In the manufacturing industry, tin bronze is widely used for gears and bearings. These components require durability and precision. The low friction properties of tin bronze enhance performance. In automotive applications, tin bronze contributes to parts that endure heavy loads. This allows for better longevity and reliability.

Tip: Regular maintenance checks can extend the life of tin bronze components. Consider checking for wear and tear regularly.

Another important area is electrical applications. Tin bronze is used for connectors and terminals. These components require excellent conductivity and strength. The resistance to oxidation is a bonus in critical electrical systems. This ensures safety and efficiency.

Tip: Ensure that tin bronze parts are installed correctly for optimal performance. Incorrect installation can lead to failures.

While tin bronze casting provides numerous advantages, it's essential to consider its cost. Sometimes, it may be more expensive than other materials. Evaluate the requirements before choosing. Balancing cost and performance is critical in decision-making.

This chart illustrates the top benefits of tin bronze precision casting across various industries. The data reflects the percentage of industries that find these benefits crucial for their operations.