The demand for high-quality, precision-engineered components is surging across various industries, driving manufacturers to adopt advanced casting techniques. Among these, Egr Ss Precision Casting has emerged as a leading methodology renowned for its exceptional accuracy and durability. According to a recent report by MarketsandMarkets, the metal casting market is projected to reach $200 billion by 2025, with precision casting methods, including Egr Ss Precision Casting, playing a crucial role in this growth due to their ability to produce intricate designs with minimal waste. This innovative technique not only enhances product performance but also significantly reduces production costs, making it an attractive option for manufacturers looking to stay competitive in a rapidly evolving marketplace. As we delve deeper into the intricacies of Egr Ss Precision Casting, we will explore its advantages, applications, and best practices for achieving superior quality in casting processes.

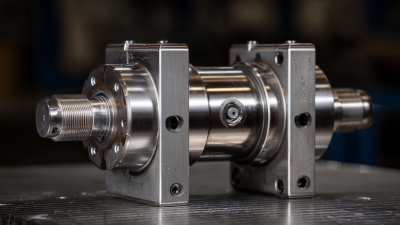

EGR SS precision casting is a manufacturing process that combines advanced technology and meticulous craftsmanship to produce high-quality stainless steel components. At its core, precision casting involves creating a mold from a pattern that reflects the exact specifications required for the final product. This technique allows for complex shapes and intricate details that traditional manufacturing methods might struggle to achieve. The use of stainless steel not only enhances the durability of the components but also improves their resistance to corrosion, making them ideal for various applications in harsh environments.

The process begins with the creation of a wax or foam pattern, which is coated with a ceramic shell. Once the shell hardens, the pattern is melted away, leaving a hollow mold. The molten stainless steel is then poured into the mold, where it cools and solidifies into the desired shape. After the casting is complete, the ceramic shell is carefully removed, and the final product undergoes various finishing processes, such as machining or polishing, to meet precise tolerances. By understanding the nuances of the EGR SS precision casting process, manufacturers can ensure the production of superior quality components that meet the rigorous demands of today’s industries.

Achieving superior quality in EGR SS (Exhaust Gas Recirculation Stainless Steel) castings hinges on several key factors that play a critical role in the casting process. One of the foremost elements is material selection. The composition of the stainless steel influences not only the durability and corrosion resistance of the castings but also the overall casting quality. Opting for high-grade stainless steel with the right alloying elements ensures that the final product meets the stringent requirements of automotive applications.

Another influential factor is the precision of the casting technique itself. Utilizing advanced techniques such as investment casting or sand casting helps to achieve finer details and better tolerances. Variations in temperature during the melting and pouring process can lead to defects like porosity or inclusions, thereby compromising the integrity of the castings. Therefore, maintaining strict temperature controls and employing effective cooling methods are essential to enhance the quality of EGR SS castings. By focusing on these critical factors, manufacturers can ensure that their products not only meet industry standards but also exceed customer expectations.

In the world of manufacturing, precision is paramount, particularly in the production of components for industries such as automotive and aerospace. EGR (Exhaust Gas Recirculation) SS (Stainless Steel) casting techniques have evolved significantly, driven by the need for superior quality and performance. Innovative methods, such as optimized mold design and advanced computer simulations, are paving the way for enhanced precision in the casting process. By utilizing sophisticated software for predictive modeling, manufacturers can identify potential defects and refine their approaches before any physical casting occurs, ensuring high-quality outcomes.

Moreover, the integration of 3D printing technology in the development of casting molds is revolutionizing the precision casting landscape. This approach allows for the creation of highly complex geometries that were previously impossible with traditional methods. The use of additive manufacturing not only speeds up the prototyping phase but also reduces material waste, ultimately leading to more efficient production processes. With these innovative techniques, EGR SS casting can achieve tighter tolerances and improve the overall performance of the final product, making it an indispensable choice for high-stakes applications.

In the realm of EGR SS precision casting, maintaining superior quality hinges on rigorous quality control measures throughout the casting process. From the initial design phase to the final inspection, each step plays a critical role in ensuring that the end product meets the stringent specifications required for performance and durability. Advanced simulation tools can help identify potential issues early in the design stage, enabling engineers to optimize the geometry and reduce the likelihood of defects.

Once the casting process begins, real-time monitoring becomes essential. Techniques such as non-destructive testing (NDT) can be employed to evaluate the integrity of the cast components without compromising their usability. Techniques like ultrasonic testing and X-ray inspection allow for the detection of internal flaws, ensuring that only materials meeting quality standards proceed to the final stages. Coupled with a structured feedback loop where data from previous productions informs future processes, these quality control measures foster a culture of continuous improvement in EGR SS precision casting operations.

| Quality Control Measure | Description | Frequency | Responsibility |

|---|---|---|---|

| Material Inspection | Verify the quality of raw materials before use. | Every Batch | Quality Control Team |

| Dimensional Verification | Measure dimensions of castings to ensure they meet specifications. | Every Hour | Production Supervisor |

| Non-Destructive Testing | Perform tests like ultrasonic or radiography to detect internal defects. | Weekly | Quality Assurance Engineer |

| Surface Quality Inspection | Check for surface defects such as cracks or blemishes. | Every Shift | Production Team |

| Traceability Checks | Ensure all materials and processes can be traced back to their source. | Monthly | Quality Manager |

In recent years, precision casting techniques have revolutionized manufacturing processes across various industries. EGR SS precision casting, known for its superior quality, plays a pivotal role in creating intricate components with exceptional dimensional accuracy. Real-world applications of this technique can be observed in sectors like automotive and aerospace, where the demand for high-performance parts is paramount. According to industry reports, precision casting can reduce material waste by up to 20%, making it a sustainable choice for manufacturers.

In recent years, precision casting techniques have revolutionized manufacturing processes across various industries. EGR SS precision casting, known for its superior quality, plays a pivotal role in creating intricate components with exceptional dimensional accuracy. Real-world applications of this technique can be observed in sectors like automotive and aerospace, where the demand for high-performance parts is paramount. According to industry reports, precision casting can reduce material waste by up to 20%, making it a sustainable choice for manufacturers.

One of the significant advantages of EGR SS precision casting is its ability to produce complex geometries that are often difficult to achieve with traditional methods. For instance, the automotive sector increasingly relies on this technique for producing lightweight components that enhance fuel efficiency and meet stringent emission standards. Adopting precision casting not only streamlines production but also results in lower overall costs.

Tips: When considering EGR SS precision casting for your projects, ensure to partner with suppliers who have a proven track record in quality assurance. Further, investing in advanced casting simulations can help in optimizing designs before production, leading to fewer iterations and ultimately saving time and resources.