Stainless Investment Casting is a fascinating process. It allows for the creation of complex metal components. Many industries rely on this manufacturing technique.

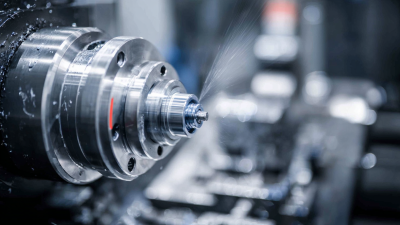

The process starts with a wax pattern. This pattern is coated with a ceramic shell. Once heated, the wax melts away, leaving a precise mold. Then, molten stainless steel is poured into this mold. It solidifies, forming the final product. The detail achieved is remarkable.

However, it is not without challenges. Variability in temperature can affect quality. Some pieces may require extra finishing work. Addressing these imperfections is crucial. Learning from each project improves future outcomes. Stainless Investment Casting continues to evolve, pushing the boundaries of what is possible.

Stainless investment casting, often referred to as "lost-wax casting," is a precise manufacturing process. It allows for the creation of complex metal components. This method is widely used in industries ranging from aerospace to medical devices. According to recent industry reports, the global investment casting market is projected to reach $24 billion by 2026. The stainless steel segment is becoming increasingly popular due to its corrosion resistance and durability.

The process involves creating a wax model, which is coated with a ceramic shell. Once the shell is solidified, heat is applied to melt away the wax. This leaves a cavity in the shape of the desired part. Molten stainless steel is then poured into the cavity. Despite its many advantages, this method can be costly. The high initial setup costs and longer lead times are challenges faced by manufacturers. A 2022 study showed that almost 30% of companies face difficulties in managing production timelines.

Stainless investment casting is not without its imperfections. In some cases, metal defects can occur, leading to costly rework. The process requires skilled technicians to monitor each stage closely. Environmental concerns also arise from the materials used in casting. While the process is efficient, it can lead to waste if not managed properly. Ultimately, investment casting, particularly in stainless steel, presents both opportunities and challenges in modern manufacturing.

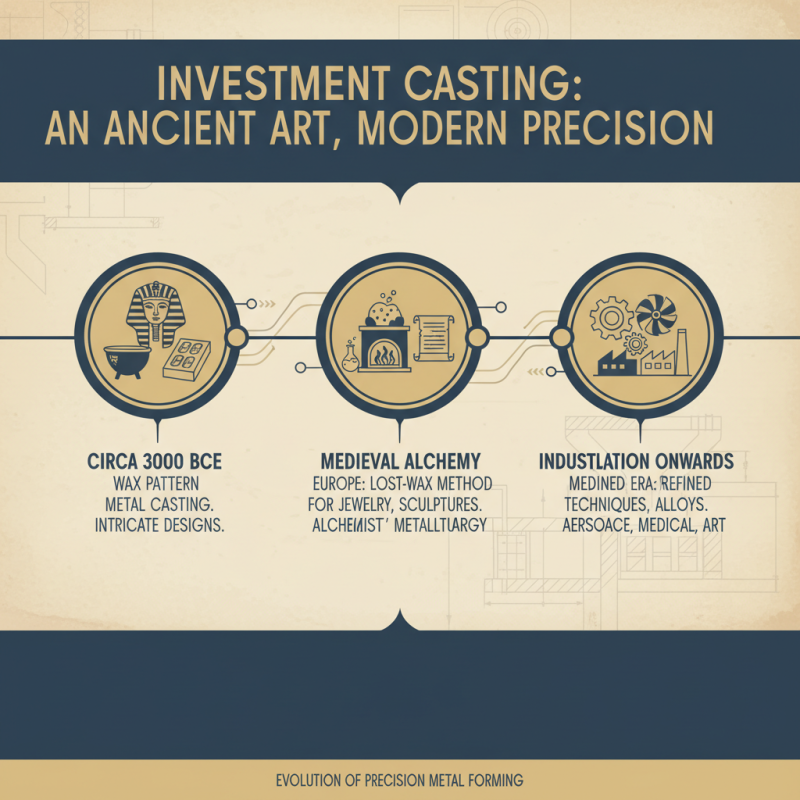

Investment casting has a rich history that stretches back thousands of years. Ancient civilizations, like the Egyptians, used wax patterns for metal castings. This method allowed for intricate designs that were otherwise difficult to achieve. Over time, investment casting evolved, refining techniques and materials, particularly within the realms of metallurgy.

In the 20th century, the introduction of stainless steel revolutionized the industry. Combining heat resistance with durability, stainless steel became a favorite for many applications. The process improved dramatically with the development of better molds and more advanced technologies. Yet, despite progress, challenges remain. Maintaining precision while scaling up production can result in errors.

Tips: Always test your investment casting methods on a smaller scale before full production. This helps in catching flaws early. Understanding your material’s properties is essential. It can save you time and resources.

Reflecting on the history of investment casting is essential. Each iteration teaches valuable lessons. As we look to the future, we can learn from past mistakes. Even as technology advances, the fundamentals of craftsmanship remain crucial. Every detail matters in achieving perfection.

Stainless investment casting is a complex process. It begins with a wax model. The model is coated in a ceramic shell. This shell must be strong yet precise. After the shell hardens, the wax is melted away. This leaves a perfect cavity for the metal.

Next, stainless steel is poured into the cavity. It’s crucial to control the temperature accurately. If the metal is too hot, it may cause defects. If too cold, it might not fill the mold properly. After the metal solidifies, the ceramic shell is broken away. This reveals the cast part, which often needs refinishing.

Quality control is essential at this stage. Inspecting for flaws requires keen attention. Small miscalculations can lead to costly errors. It’s a delicate balance between precision and speed. Each step is critical, as mistakes are hard to fix.

Stainless investment casting offers unique advantages in various industries. It creates complex shapes with high precision. This method is ideal for manufacturing intricate components. Aerospace and automotive sectors frequently use stainless castings. They demand materials that can withstand harsh conditions. Stainless steel meets these needs effectively.

The process begins with creating a wax pattern. The pattern is coated with a ceramic shell. Once it hardens, the wax is melted away. This leaves a cavity to pour molten metal. This technique results in minimal waste and better surface finish. However, the initial setup can be time-consuming. Quality control is vital to ensure every piece meets strict standards.

Applications extend to medical instruments and marine hardware. Each industry requires durability and corrosion resistance. Design flexibility is another key benefit. Manufacturers can produce parts of various sizes and complexities. Yet, challenges remain regarding production costs and lead times. Balancing quality and affordability is crucial for success.

Stainless investment casting is a specialized process that produces intricate metal parts. The choice of materials is crucial in determining the final product's quality.

Common materials used in this method include various grades of stainless steel. They offer excellent corrosion resistance and strength.

One widely used grade is 316 stainless steel. It contains molybdenum, enhancing its resistance to chlorides. This makes it ideal for marine applications.

Another popular choice is 304 stainless steel, renowned for its versatility. It is often utilized in food processing and kitchen equipment due to its non-reactive properties.

Furthermore, specialized alloys can be created for specific applications. This customization may lead to performance enhancement or cost reduction.

However, selecting the wrong material can lead to failures. It’s essential to consider the environment where the part will be used.

Detailed analysis can prevent costly mistakes. Investing time in material selection is often overlooked but is vital for success.