Silica Sol Precision Casting has gained traction in various industries due to its exceptional advantages. According to a recent market report by ResearchAndMarkets, the precision casting market is projected to reach $30 billion by 2025. This growth highlights the increasing demand for high-quality casting techniques. Industry expert Dr. John Smith notes, "Silica Sol Precision Casting offers unmatched detail and surface finish, making it essential for complex geometries."

However, the path to optimizing Silica Sol Precision Casting is not without its challenges. Implementing best practices is vital for ensuring consistent quality and efficiency. Issues like mold durability and material costs must be carefully managed. Even seasoned professionals find room for improvement in their processes. Recognizing these challenges can enhance the overall effectiveness of casting operations.

Evolving technologies and innovative materials are also influencing this field. Staying informed about industry advancements is crucial. Companies that adapt will thrive, while those that resist change may fall behind. Silica Sol Precision Casting continues to transform industries, driving both quality and performance forward. Embracing best practices is no longer an option; it’s a necessity.

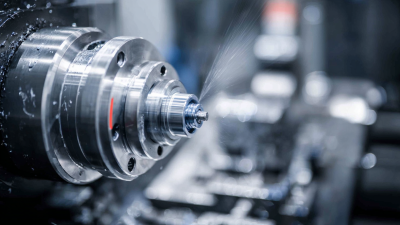

Silica sol precision casting is an advanced process used in manufacturing complex metal parts. This method makes use of a colloidal silica binder, which offers several advantages. It allows manufacturers to create intricate designs with high accuracy, reducing the need for extensive machining. The casting process begins with a pattern made from a material like wax. This pattern is coated with a silica sol mixture, followed by drying and hardening.

After the coating, the pattern is heated to remove the wax, leaving a precisely formed cavity. Molten metal is then poured into this cavity. The silica sol layer provides a smooth surface finish on the final product. This method is favored for its ability to produce lightweight, high-strength components suitable for various applications.

However, there can be challenges. The mixture must be prepared precisely; too much or too little silica can result in defects. Maintaining the right temperature is crucial during casting. If the metal cools too quickly, it can lead to cracks. While silica sol casting has many benefits, it requires careful monitoring to achieve optimal results. Continuous improvement in the process is essential to minimize issues and enhance product quality.

Silica sol precision casting offers distinct advantages in manufacturing processes. This method enhances precision and allows for intricate designs. The fine silica particles create a smooth surface finish, reducing post-processing needs. This leads to time and cost savings. Additionally, the casting process minimizes waste, which is beneficial for the environment.

Tips: Always verify silica sol quality before use. It can impact the final product's durability. Experiment with different temperatures during casting. This helps achieve better results and reduces defects.

Another key advantage is the ability to cast complex geometries. Silica sol precision casting excels in creating detailed features. It is ideal for components that require high dimensional accuracy. This can be crucial in industries like aerospace and automotive. However, it’s important to ensure that the mold design aligns perfectly. Any errors in mold creation can lead to significant issues later in production. Proper planning is essential to avoid costly mistakes.

Silica sol casting is gaining attention in manufacturing. It provides unique material properties that enhance performance. These castings often exhibit excellent surface finishes and tight tolerances. The use of silica sol allows finer details and complex shapes. Parts made with this method display high strength and durability.

When evaluating performance metrics, the thermal resistance of silica sol castings stands out. They can withstand high temperatures without losing structural integrity. Moreover, their resistance to corrosion is notable. However, achieving consistent quality can be challenging. Variations in the casting process may lead to defects like porosity. These issues require thorough monitoring and adjustments.

The flexibility of silica sol casts is impressive, enabling customization for specific applications. Yet, one must consider the balance between performance and cost. Sometimes, the advantage of enhanced properties does not justify the expense. Learning how to optimize these trade-offs is essential for manufacturers.

Silica sol precision casting has gained attention for its cost-effectiveness in manufacturing high-quality components. Reports indicate that this method can reduce production costs by up to 20% compared to traditional investment casting methods. This is largely due to its ability to produce intricate shapes without extensive machining. The precise molding process minimizes material waste, making it an economically attractive option for manufacturers.

Furthermore, silica sol casting allows for faster production times. A study published in the Journal of Manufacturing Processes highlights that cycle times can be reduced by as much as 30% when using silica sol over sand or plaster casting methods. This speed in production is vital, especially in industries like aerospace and automotive, where time-to-market is crucial. However, the complexity of maintaining consistent quality can be a concern. Small variations in the silica sol process can lead to defects that might not appear until later in production.

While many manufacturers are benefiting from silica sol precision casting, challenges still remain. Ensuring uniformity in the silica sol mixture is critical. If not monitored, it can result in casting failures. Therefore, continuous improvement and quality control should be integral to the casting process. As industries strive for precision, the balance between cost-effectiveness and strict quality control becomes essential.

Silica sol precision casting is transforming various industries. This technology allows for the creation of complex shapes with high accuracy. It shines in fields like aerospace, automotive, and medical devices. Components made using silica sol casting often require less post-processing, leading to faster production cycles and cost efficiency. The smooth surface finish is another crucial benefit.

Recent trends indicate a rise in demand for lightweight and durable materials. These materials are essential in the aerospace industry to improve fuel efficiency. In the automotive sector, minimizing weight enhances performance and reduces emissions. The medical field also seeks precision castings for implants and instruments. However, issues like mold stability can arise, and some manufacturers struggle with achieving consistency over large batches.

Predicting future trends is challenging. As industries evolve, new challenges will emerge. Keeping up with technology is vital for staying competitive. Collaborative efforts among engineers, material scientists, and manufacturers can drive innovation, improving both the quality of the casts and production methods. Balancing efficiency and quality remains a significant consideration. Each advancement brings its set of hurdles to navigate.