In the realm of manufacturing, the demand for high-quality components has led to the emergence of Precision Investment Casting as a crucial process. This advanced casting technique allows for the production of intricate geometries with superior dimensional accuracy and surface finish. According to a report by MarketsandMarkets, the global investment casting market is projected to reach USD 23.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.8%. Such growth can be attributed to the increasing use of lightweight and complex components in sectors such as aerospace, automotive, and medical devices.

Precision Investment Casting stands out due to its ability to reduce material waste and optimize production efficiency. By utilizing a wax pattern and refining the mold-making process, manufacturers can achieve tighter tolerances and minimize the need for secondary machining. A study by Technavio emphasizes that the reduced lead time and enhanced product quality associated with this technique significantly bolster its adoption in high-stakes industries. As industries continue to evolve and seek competitive advantages, Precision Investment Casting emerges as a key player in high-quality production, ensuring not only performance but also cost-effectiveness in the manufacturing landscape.

Precision investment casting is a sophisticated manufacturing process that enables the production of complex and high-quality metal parts with exceptional accuracy. This method, often referred to as lost-wax casting, involves creating a wax model of the desired part, which is then coated in a ceramic shell. Once the shell is hardened, the wax is melted away, leaving a precise mold for molten metal. This casting technique is particularly advantageous for producing components with intricate geometries that would be challenging or impossible to achieve using traditional machining methods.

According to a recent industry report by the Investment Casting Institute, the precision investment casting market is projected to grow significantly, reaching an estimated value of over $20 billion by 2026. This growth is driven by the increasing demand in aerospace, automotive, and medical industries, where precision and reliability are paramount. Research indicates that parts produced via investment casting can achieve tolerances as tight as ±0.005 inches, making it a preferred choice for high-performance applications. Furthermore, the yield rates in precision casting often exceed 90%, which minimizes material waste and contributes to overall cost-effectiveness, further solidifying its role as a key technology in high-quality production.

Precision investment casting has emerged as a cornerstone for achieving high-quality production across various industries. This sophisticated casting technique allows for the creation of complex geometries and intricate designs with remarkable accuracy. By utilizing a wax or plastic pattern that is coated with a ceramic shell, manufacturers can produce parts that have tight tolerances and smooth surface finishes. This level of precision not only enhances the aesthetic appeal of the final product but also significantly reduces the need for extensive post-casting machining, ultimately leading to shorter production times and lower costs.

Moreover, precision investment casting plays a crucial role in material efficiency. The process minimizes waste by ensuring that only the necessary amount of material is used, which is particularly beneficial when working with expensive alloys or specialty metals. Additionally, the ability to create lightweight yet strong components is especially advantageous in industries such as aerospace and automotive, where performance and reliability are paramount.

In this context, the precision casting process contributes not just to the quality of the individual components but also to the overall integrity and sustainability of the final assemblies, reinforcing its status as a vital method for high-quality production.

Precision investment casting is revolutionizing manufacturing by offering several advantages over traditional casting methods. One of the primary benefits is the superior dimensional accuracy it provides. With precision investment casting, intricately detailed designs are achieved with a minimal tolerance level, which reduces the need for extensive machining or finishing processes. This leads to not only cost savings but also enhances product reliability, resulting in higher customer satisfaction.

Additionally, the ability to create complex geometries with fewer components is another significant advantage. This method allows for the integration of multiple features into a single cast, which simplifies assembly and reduces overall production time. The flexibility in selecting various materials also enables manufacturers to tailor their products, making them suitable for a wide array of applications across different industries.

**Tips:** When considering precision investment casting, it's essential to collaborate closely with engineers to optimize design for manufacturability. Evaluate the specific requirements of your project to fully leverage the benefits of this method. Always review material compatibility to ensure the final product meets the desired performance standards.

Precision investment casting is a versatile manufacturing process widely utilized across various industries due to its ability to produce complex and high-quality components with exceptional dimensional accuracy. In the aerospace industry, for instance, this technique is employed to create lightweight, intricate parts that can withstand extreme conditions, ensuring reliability and performance in critical applications such as engine components and structural elements. The precise nature of investment casting allows engineers to design parts that optimize aerodynamics and fuel efficiency, making it a crucial element in modern aviation.

Another significant application of precision investment casting can be found in the automotive sector. The process enables the production of intricate components such as gears, brackets, and manifold assemblies that must meet stringent quality and durability standards. By using this method, manufacturers can reduce material waste and achieve superior surface finishes, which ultimately enhance the performance and longevity of automotive parts. Additionally, the ability to produce both ferrous and non-ferrous alloys through precision investment casting broadens its applicability, making it integral in producing components for electric vehicles, hybrid engines, and advanced driver-assistance systems, where precision and efficiency are paramount.

| Industry | Key Applications | Benefits of Precision Casting | Typical Materials Used |

|---|---|---|---|

| Aerospace | Engine components, turbine blades | High precision, lightweight, enhanced performance | Nickel alloys, stainless steel |

| Automotive | Transmission parts, engine brackets | Cost-effective, intricate designs, reduced waste | Aluminum alloys, steel |

| Medical | Surgical instruments, dental fixtures | High tolerance, sterilizable, biocompatible | Titanium, stainless steel |

| Oil & Gas | Valve components, pumps | Durability, resistance to harsh environments | Carbon steel, alloy steel |

| Electronics | Heat sinks, enclosures | Complex shapes, lightweight, cost-effective | Aluminum, magnesium |

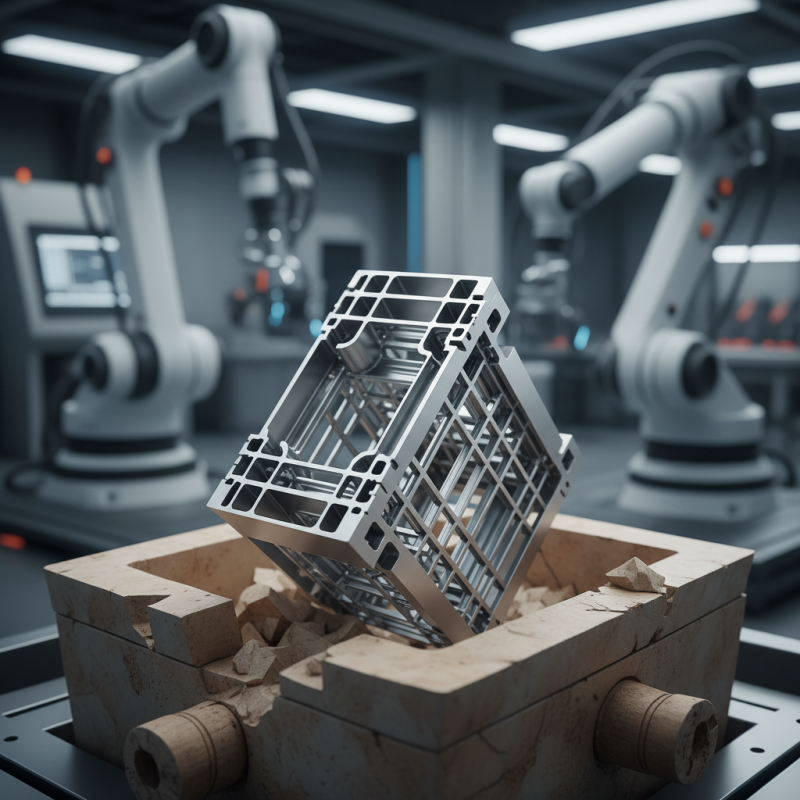

The future of precision investment casting is being shaped by several innovative trends that promise to enhance efficiency and product quality in manufacturing. One significant trend is the adoption of advanced computer-aided design (CAD) software. This technology allows for highly detailed and complex designs that were previously difficult to achieve, enabling manufacturers to create intricate components with minimal waste. Moreover, the integration of simulation tools helps to predict and rectify potential issues in the casting process, leading to faster production times and reduced costs.

Another notable innovation is the use of additive manufacturing techniques within the investment casting process. This hybrid approach allows for the rapid production of molds and cores, significantly decreasing lead times. Additionally, materials science advancements are fostering the development of new alloys and ceramics that can withstand extreme conditions, enhancing the durability and performance of cast components. These innovations not only improve the repeatability and precision of investment casting but also expand its applications across diverse industries ranging from aerospace to medical devices, marking a promising horizon for high-quality production.