In the rapidly evolving landscape of manufacturing, mastering the intricacies of Pump SS Precision Casting has become paramount for industry professionals aiming to achieve exceptional results. As noted by renowned casting expert Dr. Emily Carpenter, “The key to success in Pump SS Precision Casting lies in understanding the delicate balance of material properties and process control.” This statement underscores the importance of expertise and precision in the casting process, which is critical in producing high-quality components that meet stringent performance standards.

As we approach 2025, the demand for advanced casting techniques continues to rise, necessitating a comprehensive guide for engineers and manufacturers alike. The understanding of Pump SS Precision Casting not only enhances the efficiency of production but also ensures that the final products exhibit the durability and reliability essential for various applications. This guide will delve into the methodologies, best practices, and innovations shaping the future of Pump SS Precision Casting, equipping professionals with the knowledge they need to thrive in a competitive marketplace. Emphasizing the significance of meticulous process execution and continuous improvement, this resource aims to foster expertise and guide practitioners toward optimal casting results.

Understanding Pump SS Precision Casting involves grasping the fundamental principles and techniques that make it an efficient process in manufacturing. At its core, precision casting enables the production of intricate shapes and dimensions with high accuracy. The process, typically involving molten stainless steel, allows for a reduction in waste material, as the cast parts closely match the desired final product shape. This characteristic is crucial in industries where precision is paramount, such as aerospace and automotive sectors.

The techniques employed in Pump SS Precision Casting vary, but they generally include investment casting and lost-wax casting methods. Investment casting, known for its adaptability to complex designs, utilizes a disposable mold made from a wax pattern. The lost-wax technique enhances detail and surface finish, making it ideal for high-performance components. Mastering these techniques requires not only an understanding of the materials involved but also the thermal properties and cooling rates that affect the final outcome. Combining these concepts and techniques optimizes production processes and ensures the quality of cast components, which is vital for their intended applications.

Precision casting, particularly in pump stainless steel (SS) applications, requires specific tools and equipment to ensure optimal results. A recent report by the International Journal of Advanced Manufacturing Technology emphasized that the use of high-quality casting tools significantly reduces defects and enhances the integrity of the final product. Essential tools in this process include CNC machining centers, which allow for precise shaping of molds. The integration of 3D printing technology in mold creation is also proving to be a game changer, facilitating rapid prototypes and custom designs that traditional methods struggle to achieve.

In addition to machining tools, the selection of appropriate casting materials is crucial. Research from the American Foundry Society highlights that utilizing advanced stainless steel alloys can improve corrosion resistance and strength, vital for pump applications. Moreover, investing in equipment like induction furnaces and automated pouring systems can enhance production efficiency and consistency. As the market for precision casting grows, projected to reach $42 billion by 2026, it's clear that having the right tools and equipment is not just an option but a necessity for manufacturers aiming to stay competitive and deliver high-quality performance in their products.

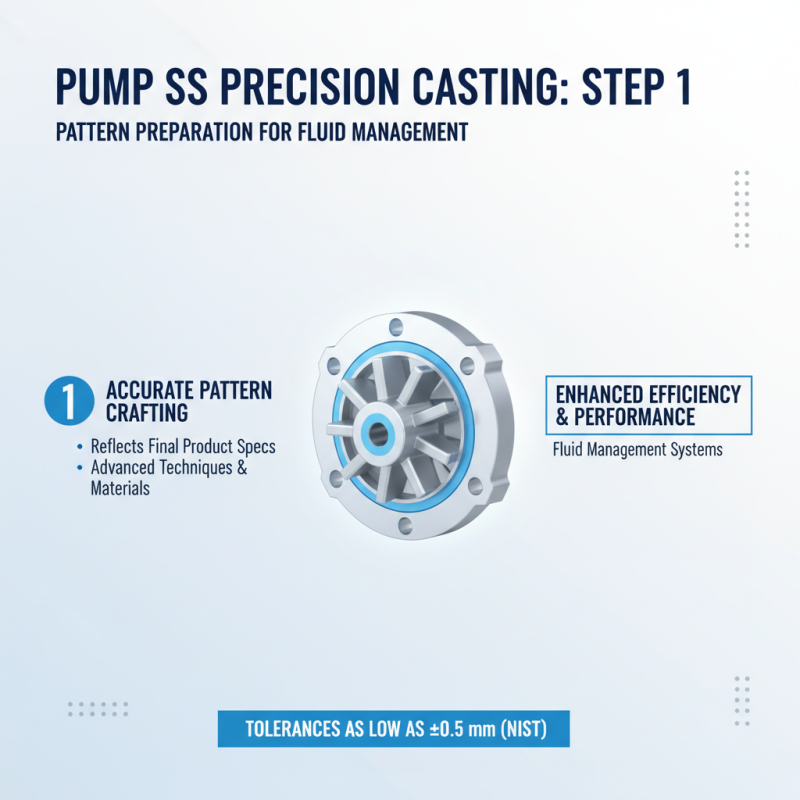

Mastering the process of Pump SS precision casting can significantly enhance the efficiency and performance of fluid management systems. The first step involves preparing the pattern, which should be crafted with a high degree of accuracy to reflect the final product’s specifications. Precision casting often yields parts with tolerances as low as ±0.5 mm, according to the National Institute of Standards and Technology. This makes it imperative to invest in advanced pattern-making techniques and materials to ensure optimal results.

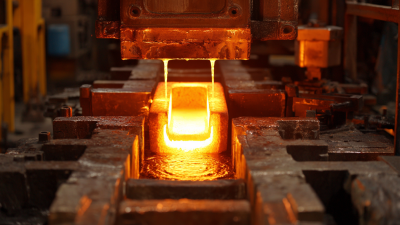

Once the pattern is prepared, the next stage is the melting and pouring of stainless steel. Utilizing proper temperature control during this stage is crucial; research shows that maintaining a melt temperature within the 1400°C-1500°C range can improve the mechanical properties of the final product. After pouring, the cooling process should be managed to prevent defects such as cracks or warping, which can negatively impact performance.

Tips: Always conduct a pre-casting inspection of your pattern for any imperfections, as these can create significant issues later in the process. Additionally, consider implementing a quality control phase after cooling to assess the integrity of the cast components. Regularly revisiting and updating your casting process based on industry reports can help in continuously enhancing the quality and efficiency of your casting operations. Data from industry analyses indicate that companies that adapt their practices based on performance metrics see up to a 30% reduction in the rate of defects.

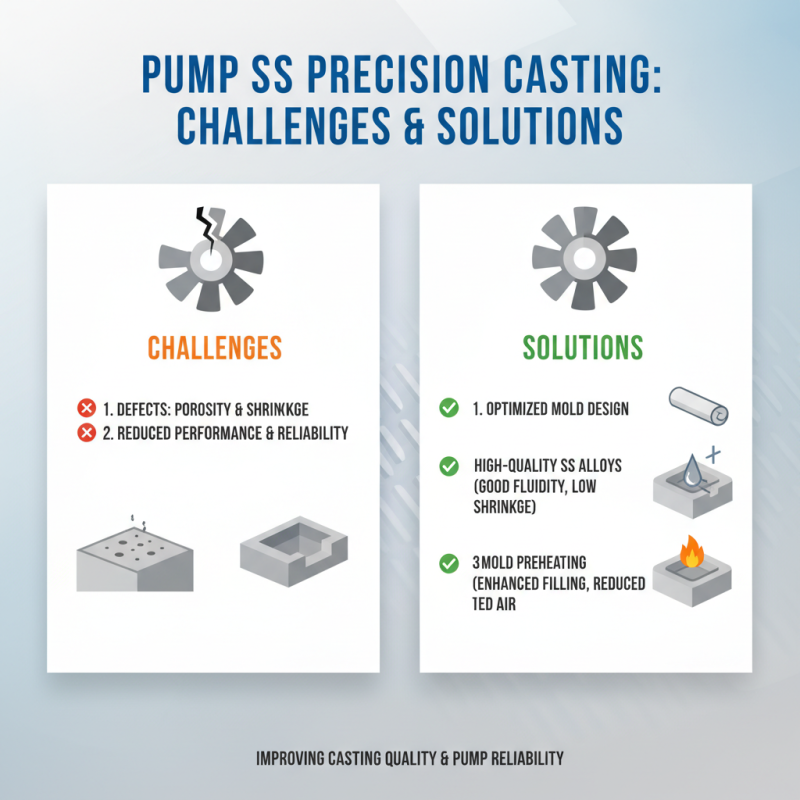

Pump SS precision casting is a complex process that often presents several challenges. One common issue is the occurrence of defects such as porosity and shrinkage in the final castings. These defects can significantly impact the performance and reliability of the pumps. To mitigate these challenges, thorough attention must be paid to the mold design and the material selection. Utilizing high-quality stainless steel alloys that possess good fluidity and low shrinkage characteristics can help in minimizing defects. Additionally, preheating the molds can enhance the filling of the cavities, reducing the likelihood of air entrapment, and thus improving the overall quality of the castings.

Another significant challenge is maintaining dimensional accuracy throughout the casting process. Variations in temperature and improper control of the cooling rate can lead to distortions. To overcome this, it is essential to implement precise temperature control measures and conduct regular monitoring throughout the casting phase. Employing advanced simulation software can also aid in predicting potential deformation and allow for necessary adjustments before the actual casting begins. By anticipating these issues and applying targeted solutions, manufacturers can improve the efficiency and reliability of their pump SS precision casting operations.

To ensure success in Pump SS production, following best practices and understanding precision casting techniques are crucial. According to a recent report published by the Casting Industry Association, the global market for precision casting is expected to grow at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2028, highlighting the increasing demand in the manufacturing sectors, especially for stainless steel pump components.

Implementing effective quality control measures throughout the casting process is essential. Regular monitoring of temperature and material properties can significantly reduce defects such as porosity and dimensional inaccuracies. Furthermore, utilizing advanced technologies like computer-aided design (CAD) and finite element analysis (FEA) can enhance the design and production efficiency, ensuring that components meet both functional and regulatory standards. A study by the American Foundry Society shows that employing these technologies can decrease production lead times by as much as 30%, which is critical in maintaining competitive advantage in the rapidly evolving market.

In addition, workforce training should not be overlooked. Investing in skill development for workers can lead to a notable increase in productivity and product quality. Reports from the National Institute of Standards and Technology indicate that companies with well-trained personnel in precision casting experience 15% higher operational efficiency. Integrating these practices into your production strategy will not only optimize results but also position your business favorably within the growing precision casting industry.

This chart illustrates the production efficiency of Pump SS precision casting over different months, showcasing the improvements and trends in production yield.