In the realm of marine engineering and craftsmanship, Marine Copper Casting stands out as a critical process that combines artistry with advanced metallurgical techniques. Recent industry reports indicate that the global market for copper casting is projected to grow significantly, driven by increasing demand in sectors such as marine construction, shipbuilding, and decorative arts. According to a 2022 study by Allied Market Research, the marine sector alone constitutes a substantial portion of the overall copper casting market, reflecting the material's importance in producing durable and corrosion-resistant components suitable for harsh marine environments.

For beginners eager to delve into the world of marine craftsmanship, mastering Marine Copper Casting techniques can open doors to a myriad of opportunities. Whether it is creating intricate marine fittings or essential components for vessels, understanding the nuances of this craft is vital. As educational resources become more accessible and community workshops proliferate, aspiring artisans can acquire the skills necessary to excel in this specialized area. This guide aims to provide a comprehensive overview of the fundamental techniques and best practices that will empower novices to embark on their journey in marine copper casting, ensuring they can create high-quality pieces that meet industry standards while also embracing the creative aspects of the craft.

Mastering marine copper casting techniques can be an exciting journey for beginners, as it blends artistry with craftsmanship. At its core, marine copper casting involves the process of melting copper and pouring it into molds to create intricate designs often used in marine applications such as nautical sculptures or functional items like bells. Understanding the basic principles of this technique paves the way for creating beautiful and durable items that can withstand the elements.

Tips: Start with the Right Tools

First, ensure you have the necessary tools for safe and effective casting. A good crucible, proper heating source, and high-quality molds are essential. Always prioritize safety by wearing appropriate protective gear, including gloves and goggles, as molten metal can be extremely dangerous.

As you get comfortable with the basics, focus on mastering the pouring technique. Even pressure and a steady hand are crucial for avoiding flaws in your castings. Practice with smaller molds before advancing to larger, more complex designs. Experimenting with alloy mixtures can also yield unique finishes and properties, enhancing your artistic expression on marine-themed pieces.

Tips: Experiment and Learn

Don’t hesitate to experiment with various techniques such as sand casting or lost wax methods. Each approach has its unique advantages and can produce different textures and details. Document your process and results to refine your skills over time and understand what works best for you in this captivating art form.

When it comes to marine copper casting, having the right tools and materials is crucial for beginners looking to master this art. First and foremost, you'll need a reliable melting furnace that can reach high temperatures to melt copper effectively. A crucible made of graphite or ceramic is essential for containing the molten metal. It's also beneficial to have a good set of tongs for handling the crucible safely and a heat-resistant work surface to protect your workspace.

In addition to these basic tools, you'll require some basic materials. High-quality copper scrap or ingots are necessary for casting, and it's wise to invest in a flux to help reduce oxidation during melting. Molds, made from sand or other materials, are needed to shape the molten copper once it’s poured. Safety gear, including gloves, goggles, and an apron, is essential to protect against burns and accidents.

Tips: Always start with small batches of copper to get comfortable with the melting process. Keep your workspace organized to avoid mishaps, and ensure you have all your materials on hand before beginning. Practicing good hygiene and safety measures will not only protect you but also improve your casting results as you progress.

To begin your journey into marine copper casting, it’s essential to familiarize yourself with the basic tools and materials. Start with high-quality copper ingots, a suitable crucible, and a reliable heat source. Safety gear, including gloves and eye protection, is crucial when dealing with molten metal.

The first step in the casting process involves melting the copper until it reaches a liquid state. Using a furnace or a propane torch, heat the copper to its melting point, which is around 1,984°F (1,085°C). Once melted, carefully pour the molten copper into a pre-prepared mold, ensuring that the mold is designed for copper casting to avoid any complications during the cooling process.

Tips: Make sure your mold is dry and clean to achieve a smoother finish. Preheating the mold can also help to prevent the copper from solidifying too quickly, ensuring better detail in your cast. Finally, be patient as your casting cools down; removing it too soon can lead to warping or damage.

After the casting has cooled and solidified, carefully remove it from the mold. You may need to clean and polish the surface to achieve the desired aesthetic. This hands-on approach not only enhances your skills but also allows for creativity in your marine copper casting projects.

When diving into marine copper casting, safety must be the top priority for beginners. The process involves handling molten metal, which can reach extremely high temperatures, posing significant risks if proper precautions are not taken. Therefore, it is essential to equip yourself with personal protective gear, including heat-resistant gloves, safety goggles, and flame-retardant clothing. Additionally, a well-ventilated workspace is crucial to reduce the inhalation of harmful fumes that can be emitted during the melting process.

Best practices in copper casting also play a vital role in ensuring a safe and successful experience. Before starting any casting project, it's imperative to conduct a thorough assessment of your equipment and workspace. Ensure that all tools are in good condition and that flammable materials are stored away from the casting area. Familiarizing yourself with the melting point of copper, which is around 1,984°F (1,085°C), allows for better preparation and control when managing the heat source. Lastly, following a step-by-step procedure and working with a knowledgeable partner can help mitigate risks, making the learning experience both safer and more enjoyable.

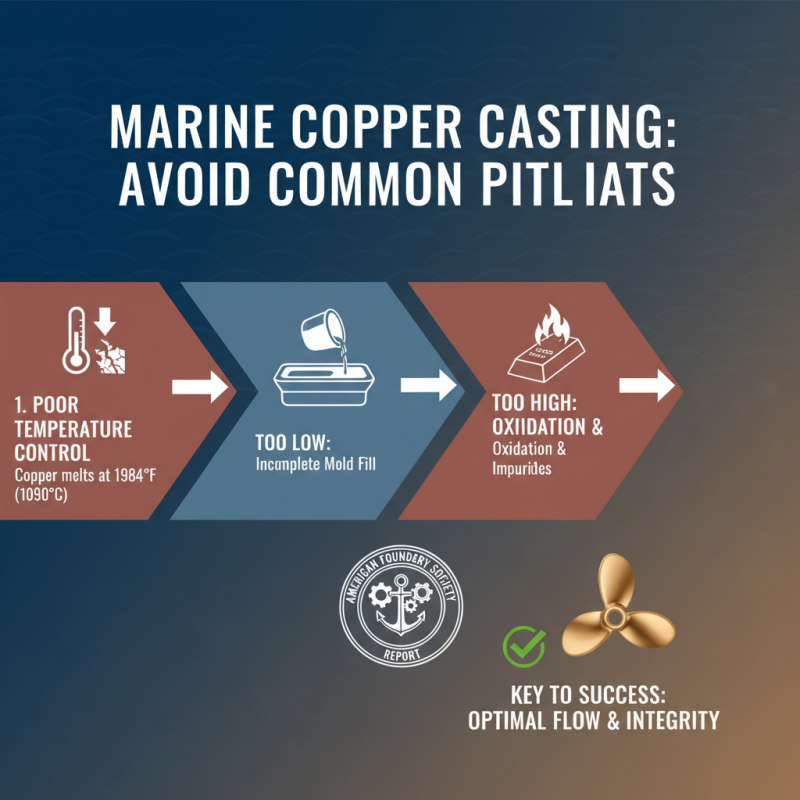

When starting with marine copper casting, beginners often fall into several common pitfalls that can derail their journey. One significant mistake is neglecting the importance of proper temperature control during the melting process. According to a report by the American Foundry Society, maintaining the correct melting temperature for copper (around 1,984°F or 1,090°C) is crucial for achieving optimal flow and reducing impurities. A temperature that’s too high can lead to oxidation, while one that’s too low might result in improper mold filling, affecting the final product’s quality and integrity.

Additionally, beginners often overlook the necessity of a well-prepared mold. A study by the International Journal of Metalcasting emphasizes that mold preparation, including proper ventilation and surface treatment, plays a critical role in the success of the casting process. Poorly prepared molds can lead to defects such as surface blemishes and inconsistent dimensions, which are commonly reported issues among novice casters. To avoid these mistakes, investing time in understanding the principles of mold design and ensuring meticulous preparation will significantly enhance your casting outcomes and overall experience in marine copper casting.