In the realm of precision engineering, the selection of high-quality Investment Casting Supplies is paramount to achieving optimal results in the casting process. As we approach 2025, industry trends indicate a growing demand for advanced materials and technologies that cater to the evolving needs of manufacturers. According to a recent report by Gardner Research, the global investment casting market is projected to reach USD 27.9 billion by 2026, spurred by advancements in the aerospace and automotive sectors. This underscores the importance of choosing the right supplies that not only enhance production efficiency but also ensure superior casting integrity.

Industry expert Dr. Emily Carter, a leading consultant in casting technologies, emphasizes that “the choice of Investment Casting Supplies directly influences the overall quality and performance of the final product.” Her insights highlight the need for manufacturers to remain vigilant about the products they select, as the landscape of investment casting continues to innovate. With a focus on sustainability and performance, the right supplies will not only facilitate compliance with stringent industry standards but also position businesses for success in a competitive marketplace. As we delve into this ultimate guide, we will explore the essential criteria for choosing the best Investment Casting Supplies for your operations.

When selecting investment casting supplies in 2025, it's essential to consider several key factors that can significantly influence the quality and efficiency of the casting process. One of the primary considerations is the material used for the investment molds. According to a recent industry report by Grand View Research, high-performance ceramic materials are increasingly favored due to their superior thermal stability and resistance to thermal shock. These properties not only improve the precision of the cast parts but also enhance their durability, making them suitable for a diverse range of applications across industries such as aerospace and automotive.

Another critical aspect is the technology used in the casting process. The rise of advanced manufacturing technologies, such as 3D printing and improved wax pattern production techniques, sets a new standard for investment casting. A report by Markets and Markets indicates that companies adopting these technologies can achieve up to 30% reductions in waste and lead times, positioning themselves competitively in the marketplace. Therefore, when choosing investment casting supplies, it's vital to stay abreast of the latest innovations and select products that align with these advancements to ensure optimal performance and cost-efficiency.

Investment casting is a precise and versatile manufacturing process that relies heavily on selecting the right materials. For high-quality investment casting, key factors to consider include the type of alloy and its physical properties, which significantly affect the final product's performance. Commonly used materials in investment casting include carbon steel, low-alloy steel, and high-alloy steel, each offering unique benefits tailored to specific applications. Carbon steel is highly regarded for its strength and durability, making it suitable for general-purpose components. On the other hand, low-alloy steels provide enhanced mechanical properties and better resistance to wear and corrosion, which is essential for demanding environments.

Investment casting is a precise and versatile manufacturing process that relies heavily on selecting the right materials. For high-quality investment casting, key factors to consider include the type of alloy and its physical properties, which significantly affect the final product's performance. Commonly used materials in investment casting include carbon steel, low-alloy steel, and high-alloy steel, each offering unique benefits tailored to specific applications. Carbon steel is highly regarded for its strength and durability, making it suitable for general-purpose components. On the other hand, low-alloy steels provide enhanced mechanical properties and better resistance to wear and corrosion, which is essential for demanding environments.

When choosing materials for investment casting, it is crucial to evaluate the intended application and operating conditions. High-alloy steels, for instance, are often selected for their exceptional resistance to oxidation and high temperatures, making them ideal for components used in extreme environments. Additionally, the melting point and fluidity of the chosen alloy play a critical role in the casting process's efficiency and the quality of the final casting. As the industry progresses towards 2025, understanding these material properties will be vital for manufacturers striving to achieve superior product performance and reliability in their investment casting operations.

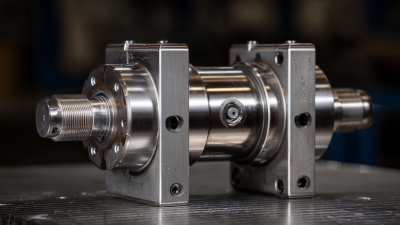

When it comes to efficient investment casting processes, having the right equipment and tools is a game changer. Investing in high-quality melting furnaces, for instance, guarantees precise temperature control, which is vital for achieving the desired metal properties. Additionally, consider using CNC machining tools for creating molds. These tools not only provide accuracy but also significantly reduce the production time, making your casting process more efficient.

Tips: Always assess the specific requirements of your projects before purchasing equipment. Look for versatile tools that can adapt to various alloy materials, as this flexibility will save you both time and costs. It’s also beneficial to invest in automation technologies that streamline the casting process, cutting down manual labor and minimizing human error.

Moreover, don’t overlook the importance of auxiliary tools such as quality inspection systems and melting crucibles. These components play a crucial role in maintaining the integrity and quality of the cast parts. Prioritize purchasing suppliers who offer comprehensive support and training on the equipment to ensure you maximize their potential in your casting operations.

When it comes to investment casting supplies, selecting the right products is crucial for achieving high-quality results in your projects. In this comparative review, we explore leading brands that offer innovative solutions designed for accuracy, durability, and efficiency in the casting process. Brands like BCN Technical Services, Phase 2 Materials, and Metal Technologies stand out for their commitment to advanced materials and customer support, making them reliable choices for professionals in the field.

Tip 1: Always consider the specific requirements of your casting projects when choosing supplies. Different brands offer various types of materials such as ceramics, wax patterns, and casting metals. Analyze your needs carefully to select the best products that meet your specifications.

Tip 2: Engage with industry forums and product reviews to gather insights on user experiences with different brands. This can help you make a more informed decision, as real-world feedback often highlights strengths and potential issues that manufacturers may not disclose.

By prioritizing quality and performance, you can enhance the overall success of your investment casting operations and ensure optimal outcomes in 2025 and beyond.

| Product Type | Material | Size Range (mm) | Weight Capacity (kg) | Temperature Resistance (°C) | Cost ($) |

|---|---|---|---|---|---|

| Wax Pattern | Thermoplastic Wax | 50-300 | 1-5 | 60 | 20 |

| Investment Casting Shell | Silica Sand | 100-600 | 5-20 | 1000 | 50 |

| Coating Material | Zircon Sand | 75-350 | 3-15 | 1500 | 30 |

| Refractory Material | Alumina | 100-500 | 5-30 | 1700 | 40 |

| Metal Alloys | Stainless Steel | 5-1000 | 10-150 | 1100 | 100 |

As we look toward 2025, the investment casting industry is poised for significant innovation, driven by advancements in materials, processes, and technologies. A report from Smithers Pira indicates that the global market for investment casting is expected to grow at a CAGR of 5.1%, reaching approximately $32.6 billion by 2025. This anticipated growth highlights the increasing demand for lightweight and high-strength components, particularly in aerospace and automotive sectors.

Key trends emerging in investment casting include the adoption of 3D printing technologies and the development of advanced alloy materials. Research from the Fraunhofer Institute suggests that integrating additive manufacturing can enhance design flexibility and reduce lead times, making it an attractive option for custom components. Additionally, the push for sustainability is prompting manufacturers to explore eco-friendly materials and processes, such as water-soluble ceramic molds that minimize waste and improve overall efficiency. This shift is expected to reshape standard practices and prioritize greener solutions in investment casting by 2025.