Investment casting, also known as lost-wax casting, has long been a staple technique in various industries, celebrated for its ability to produce intricate and precise components. As we approach 2025, the landscape for investment casting products is evolving rapidly, fueled by technological advancements and shifting market demands. This introduction explores the latest innovations and trends that are poised to redefine the investment casting sector, highlighting the products that industry professionals should keep an eye on.

In recent years, the drive for sustainability and efficiency has encouraged manufacturers to adopt advanced materials and processes, enhancing the overall quality of investment casting products. From aerospace to automotive applications, the focus on lightweight yet durable solutions is becoming paramount. Furthermore, integrating smart manufacturing technologies and automation is enabling faster production cycles and reduced costs, positioning investment casting as a competitive option in today's marketplace.

As we delve deeper into the world of investment casting products, it becomes clear that staying ahead of these trends is crucial for businesses aiming to capitalize on new opportunities. By analyzing the innovations set to impact the industry, we can appreciate how investment casting products will not only meet but exceed the expectations of the future.

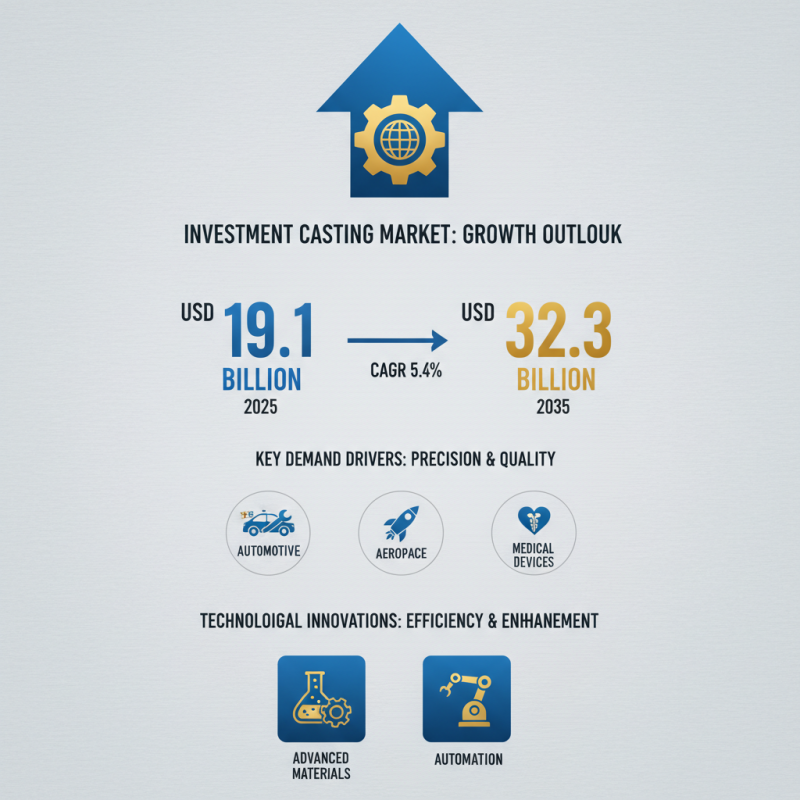

The investment casting market is experiencing significant growth, projected to rise from USD 19.1 billion in 2025 to USD 32.3 billion by 2035, reflecting a compound annual growth rate (CAGR) of 5.4%. This increase is fueled by advances in technology and innovations within the industry, which are reshaping manufacturing processes and product offerings. Companies are increasingly adopting investment casting due to its precision and ability to produce complex geometries, making it ideal for sectors like aerospace, automotive, and medical devices.

In addition to technological advancements, market dynamics are influenced by increasing demand for lightweight materials and the trend towards sustainability. As industries seek to improve fuel efficiency and reduce emissions, investment casting provides a solution with materials such as aluminum and titanium. According to a comprehensive analysis by MarketsandMarkets, the global investment casting market is positioned for continued expansion as companies innovate and enhance their production capabilities, keeping pace with evolving industry needs. Consequently, stakeholders in the investment casting market should pay close attention to emerging trends and technologies that could define success in the years to come.

The landscape of investment casting is set to be transformed by emerging technologies, particularly the integration of 3D printing. This innovative approach allows for the creation of complex geometries and intricate designs that traditional casting methods struggle to achieve. Through additive manufacturing, manufacturers can produce molds and cores with precision, reducing material waste and lead times significantly. As the technology continues to evolve, the ability to create lightweight components tailored to specific applications becomes more feasible, offering a compelling advantage in sectors such as aerospace and automotive.

In addition to 3D printing, advancements in materials science are paving the way for new alloys and composites that enhance the performance of investment cast products. These materials are engineered to withstand extreme temperatures and pressures, broadening the scope of applications. Furthermore, automation and AI-driven processes are streamlining production, enabling companies to maintain competitive edges through improved efficiency and quality control.

As these trends gain momentum, they promise to redefine the future of investment casting, making it an exciting field to watch in the years ahead.

The investment casting industry is witnessing a transformative shift towards sustainability, driven by increasing environmental awareness and regulatory pressures. Companies are adopting practices that minimize waste and energy consumption, highlighting the importance of sustainable materials and manufacturing processes. Innovations such as the use of bio-based waxes and advanced ceramic molds are gaining traction, allowing for a significant reduction in the carbon footprint associated with traditional casting methods.

Moreover, the integration of digital technologies is enhancing sustainability efforts. Companies are leveraging data analytics to optimize resource usage and reduce excess material in the casting process. By implementing Industry 4.0 technologies, such as IoT and AI, manufacturers can predict maintenance needs and improve efficiency, thereby decreasing energy expenditures.

The commitment to sustainability not only appeals to environmentally conscious consumers but also positions companies competitively in a rapidly evolving marketplace. As investment casting leaders embrace these trends, they pave the way for a greener future while ensuring innovation and economic viability.

The demand for investment casting products is expected to see substantial growth in 2025, driven primarily by key industries such as aerospace, automotive, and electronics. The investment casting market is projected to reach a valuation of $144.17 billion, with a compound annual growth rate of 12.9% from 2025 to 2033. This increase can be attributed to the rising need for precision components that can withstand extreme conditions and the growing adoption of lightweight materials in manufacturing processes.

In the semiconductor industry, the market for etching equipment is also experiencing significant expansion, with projections estimating a market size of $14.51 billion in 2024, growing to $28.26 billion by 2032. The ongoing advancements in technology demand more sophisticated manufacturing processes, pushing industries to seek out high-quality investment casting solutions. As these industries evolve, the innovations in investment casting will continue to play a crucial role in meeting the diverse needs of the market and supporting the development of cutting-edge products.

The investment casting market is poised for significant growth in the coming years. As reported, the market was valued at USD 19.1 billion in 2025 and is projected to reach USD 32.3 billion by 2035, reflecting a compound annual growth rate (CAGR) of 5.4%. This growth can be attributed to increasing demand across various industries, including automotive, aerospace, and medical devices, where precision and quality are paramount. Innovations in investment casting technology, such as the use of advanced materials and automation, are expected to drive efficiencies and enhance product offerings.

In parallel, the aircraft investment casting market specifically is on track to expand considerably, from a value of USD 8.6 billion in 2024 to an anticipated USD 12.0 billion by 2032. This surge reflects a broader trend within the aerospace sector, where lightweight and complex component designs are becoming more prevalent. The increasing emphasis on fuel efficiency and performance is fueling new applications for investment casting, highlighting the importance of continuous development and adaptation within this dynamic market landscape.