In an increasingly competitive global market, the demand for high-quality components has never been more critical. Among these essential components, Pump Ss Precision Casting stands out for its unparalleled durability and performance. Chinese manufacturers have embraced advanced technologies and stringent quality control measures, ensuring that their products meet international standards. This commitment to excellence has allowed Chinese factories to deliver Pump Ss Precision Castings that not only meet but exceed the expectations of global buyers. As we explore the journey of these remarkable products, we'll uncover how "中国制造,品质升级,畅销全球" encapsulates the transformation of Chinese manufacturing from cost-driven production to a focus on superior quality, making it a trusted partner for industries around the world.

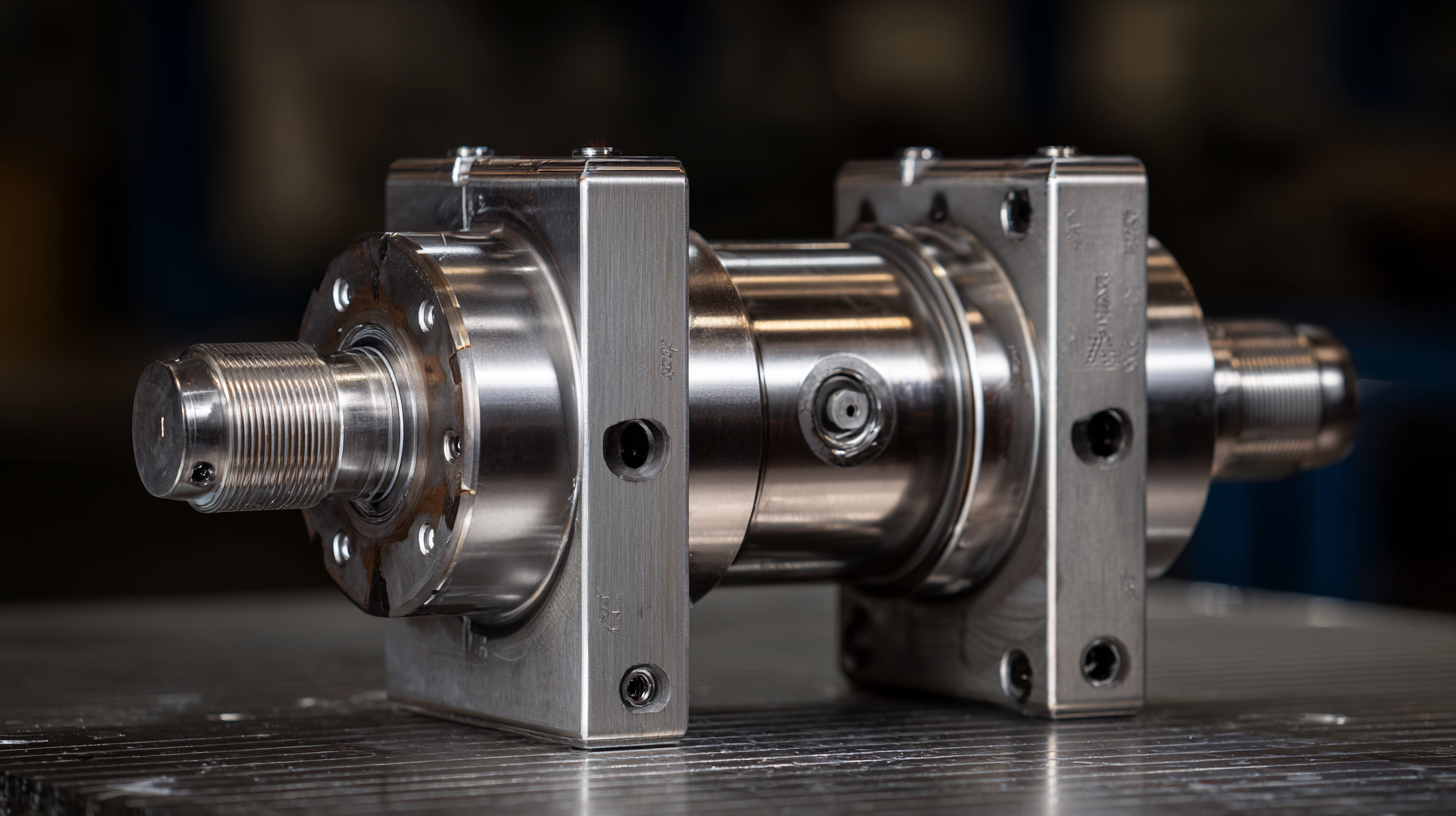

When it comes to pump manufacturing, stainless steel (SS) precision casting is paving the way for superior quality and performance. The precision casting process allows for intricate designs and components to be created with high accuracy, ensuring optimal functionality. This method not only enhances durability but also improves resistance to corrosion, making SS pumps ideal for a variety of demanding applications.

Tips for selecting the right SS precision casting manufacturer include evaluating their quality assurance processes and certifications. Reliable factories should adhere to international standards and conduct thorough inspections to guarantee that their products meet strict performance criteria. Additionally, consider their experience in the industry; established manufacturers are more likely to deliver consistent quality and innovative solutions.

Another important aspect is to seek manufacturers that employ advanced casting technologies. Modern techniques, such as investment casting, can produce components with excellent surface finishes and minimal post-processing requirements. This can lead to further cost savings and efficiency in the production line. By partnering with the right SS precision casting factory, global buyers can ensure they receive top-tier products that boost performance and reliability in their pump systems.

Global buyers are increasingly choosing Chinese casting factories due to a

combination of superior quality, competitive pricing, and innovative manufacturing techniques. The precision

casting process employed by these factories ensures that every pump part produced meets rigorous international

standards, giving buyers confidence in their durability and performance. Additionally, Chinese factories leverage

advanced technology, streamlining production and enhancing quality control, which ultimately leads

to better products.

Global buyers are increasingly choosing Chinese casting factories due to a

combination of superior quality, competitive pricing, and innovative manufacturing techniques. The precision

casting process employed by these factories ensures that every pump part produced meets rigorous international

standards, giving buyers confidence in their durability and performance. Additionally, Chinese factories leverage

advanced technology, streamlining production and enhancing quality control, which ultimately leads

to better products.

Tips for buyers considering precision casting from China include researching factory certifications and customer reviews. This due diligence can help ensure that you partner with a reliable manufacturer. It’s also wise to request samples before making a bulk order, allowing you to assess the quality of the casting firsthand.

Another key reason for the growing preference for Chinese casting factories is their nimbleness in adapting to market demands. With the rapid evolution of industries such as electric vehicles, Chinese manufacturers are at the forefront, continuously innovating to meet the unique requirements of various sectors. Establishing a relationship with a Chinese factory that stays updated on industry trends can be highly beneficial for global buyers.

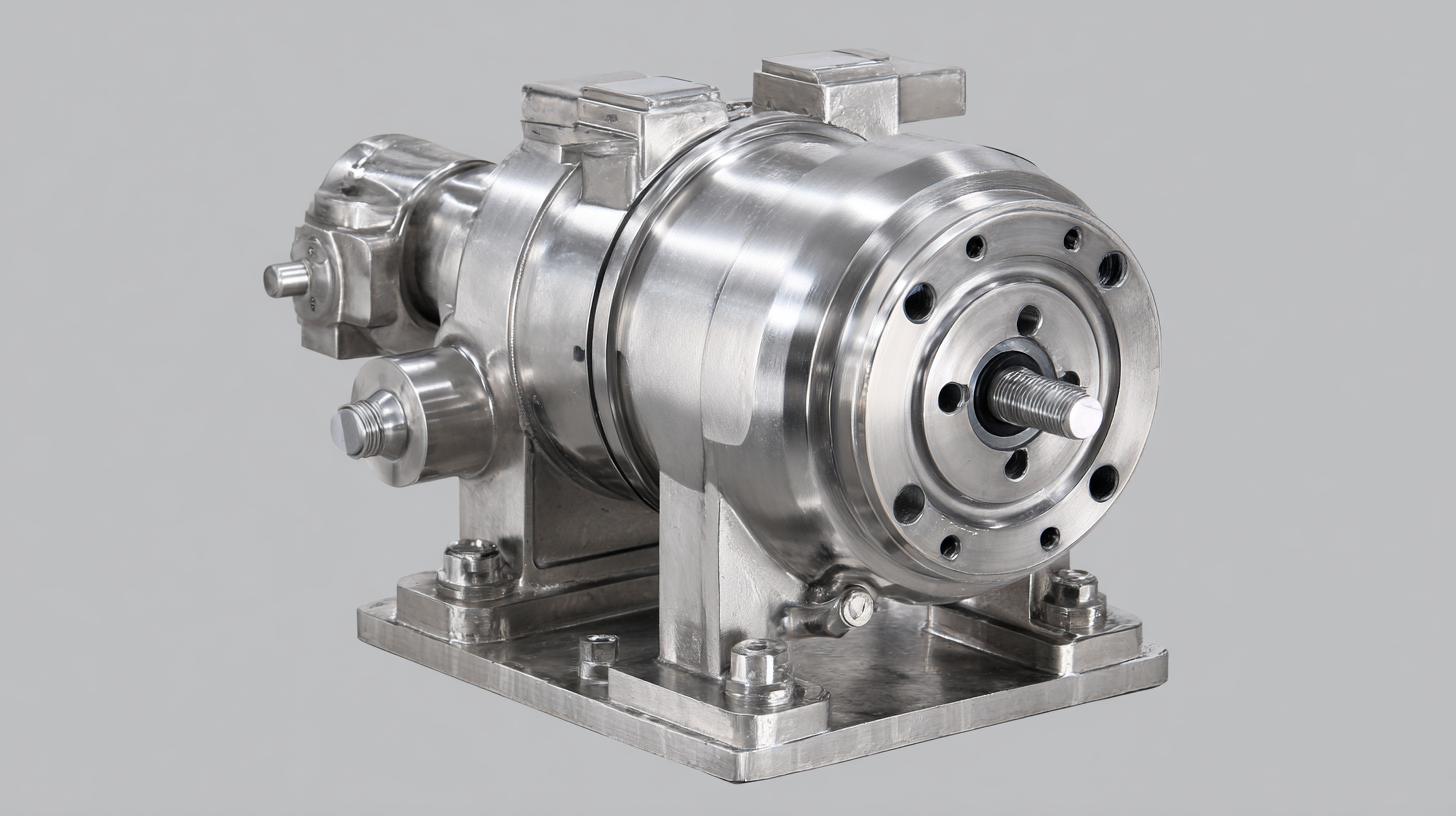

When it comes to selecting high-quality pumps, understanding the key quality indicators of stainless steel (SS) precision casting pumps is crucial for global buyers. Firstly, the material composition plays a vital role in the durability and performance of these pumps. Top manufacturers ensure the use of cold-worked stainless steel with precise chemical properties, enhancing corrosion resistance and longevity in various environments.

Secondly, the accuracy of the casting process directly impacts the efficiency of the pumps. Advanced techniques like investment casting allow for intricate designs and smooth finishes, which are essential for optimal fluid flow and reduced operational friction. Additionally, the dimensional accuracy must adhere to stringent standards to ensure interchangeability and compatibility with existing systems.

Lastly, rigorous testing protocols, including pressure tests and non-destructive examination, serve as essential quality checks before the pumps are shipped. These procedures ensure that any potential defects are identified and rectified, ultimately assuring buyers of the pumps' reliability and performance. By prioritizing these key quality indicators, global buyers can confidently invest in SS precision casting pumps from reputable China factories, knowing they are acquiring superior products that meet their needs.

| Quality Indicator | Description | Expected Value | Measurement Method |

|---|---|---|---|

| Dimensional Accuracy | Degree to which the pump matches design specifications | ±0.1 mm | CMM Inspection |

| Material Composition | Quality of stainless steel used in casting | SS 304/316 | Spectrometer Analysis |

| Surface Finish | Roughness level of the casting surface | Ra 0.8 µm | Surface Roughness Tester |

| Mechanical Strength | Resistance to deformation under load | ≥ 210 MPa | Tensile Testing |

| Leakage Rate | Amount of fluid leaking over time | ≤ 0.1 L/min | Pressure Testing |

The advancement of modern technology has significantly transformed pump production efficiency, particularly in factories specializing in precision casting. Automation, for instance, streamlines the manufacturing process, enabling faster production rates without compromising quality. Robotics and AI-driven systems can now perform tasks such as casting, machining, and assembly with remarkable precision, reducing the likelihood of human error and ensuring consistent output. This technological integration not only shortens production cycles but also enhances the capability to meet increasing global demands.

Moreover, modern technology facilitates extensive quality control measures throughout various stages of production. Real-time monitoring systems and data analytics allow manufacturers to track the quality of materials and processes, identifying potential issues before they escalate. This proactive approach ensures that every pump produced meets stringent international standards, providing buyers with superior, reliable products. As a result, global buyers are increasingly recognizing the advantages of sourcing pumps from Chinese factories, which leverage cutting-edge technology to deliver unparalleled quality and efficiency throughout their operations.

As the global pump industry continues to innovate, recent trends highlight the significant role that China plays in meeting international demands. According to a report by Research and Markets, the global pump market is projected to reach USD 85 billion by 2027, growing at a CAGR of 4.1% from 2020 to 2027. With an increasing focus on efficiency, durability, and adaptability, Chinese manufacturers are positioning themselves as leaders in precision casting technologies, providing high-quality stainless steel pumps that meet diverse industrial needs.

One of the key trends shaping the pump industry is the shift towards sustainable solutions. Industry leaders are looking for energy-efficient products that reduce environmental impact. Chinese factories, with their advanced manufacturing techniques, are responding to this shift by implementing lean production practices and investing in innovative materials. This not only ensures superior quality pumps but also supports global buyers in meeting sustainability targets.

**Tips for Global Buyers:** When sourcing pumps from China, consider manufacturers that prioritize quality certifications and environmental standards. Additionally, engaging in direct communication can lead to better customization options and faster response times. Always request detailed quality reports to ensure that the production aligns with your specific requirements.