In today’s rapidly evolving manufacturing landscape, the demand for high precision and efficiency has never been greater, particularly within industries relying on Egr Ss Precision Casting. According to a recent industry report by Smithers, the global market for precision casting is projected to reach $45 billion by 2025, driven by advancements in technology and increasing applications in aerospace, automotive, and medical sectors. Egr Ss Precision Casting techniques, known for their superior dimensional accuracy and surface finish, play a pivotal role in meeting these demands.

As manufacturers seek to streamline operations and enhance product quality, implementing the best strategies in Egr Ss Precision Casting becomes essential. This blog will explore top strategies that can revolutionize manufacturing processes, ensuring competitiveness in an ever-changing market.

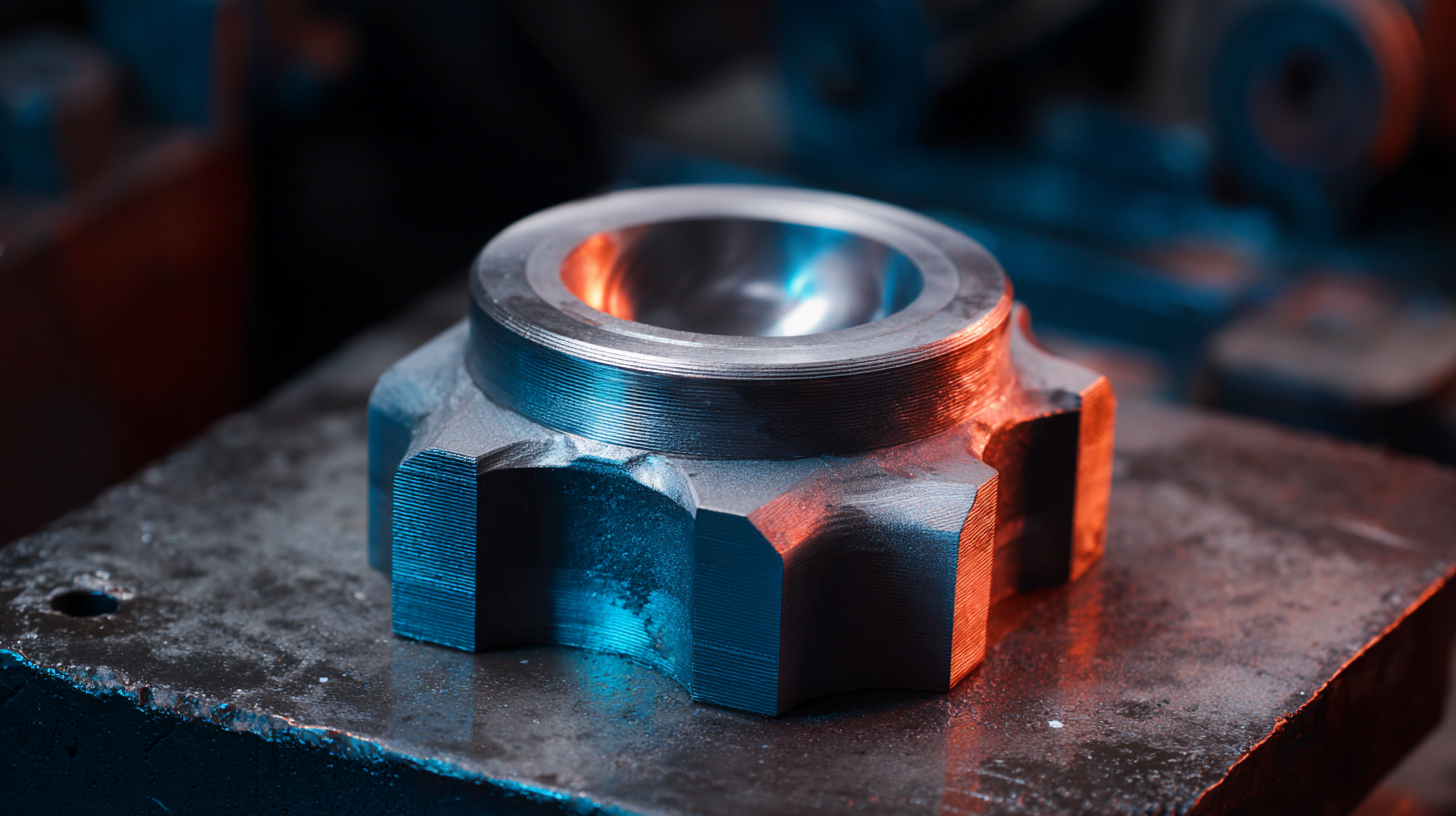

EGR SS precision casting techniques are renowned for their ability to produce components with exceptional accuracy and surface finish. The defining characteristics of these techniques are their ability to maintain tight tolerances and complex geometries, making them ideal for industries that demand high-quality parts. This method utilizes stainless steel, which not only offers durability but also enhances corrosion resistance, making it suitable for challenging environments. The process involves creating molds from high-quality patterns, ensuring that the final product closely resembles the original design.

In terms of applications, EGR SS precision casting is extensively used in the automotive industry, particularly for the production of engine components and exhaust systems. Its ability to withstand high temperatures and pressures makes it a preferred choice for critical parts that require reliability and longevity. Furthermore, this technology is beneficial in the aerospace sector, where weight and precision are paramount. The use of precision casting allows manufacturers to produce lightweight structures without compromising on strength, thereby improving overall efficiency and performance.

Precision casting techniques play a crucial role in manufacturing efficiency, especially in the production of high-quality metal components across various industries. The investment casting market is expected to reach USD 27.22 billion by 2032, demonstrating a robust CAGR of 5.1% from 2023. This growth indicates a rising demand for precision cast products, largely driven by advancements in technology and increasing applications in sectors such as aerospace, automotive, and medical devices.

Various types of precision cast products include die casting, investment casting, and sand casting, each offering unique benefits suited to different manufacturing needs. For instance, die casting, particularly pressure and vacuum types, is preferred for producing complex shapes in automotive parts. As highlighted in recent reports, the demand for die casting services is expected to grow significantly through 2035, propelled by emerging trends that emphasize lightweight and durable components. Similarly, modern advancements in additive manufacturing are enabling the production of intricate designs that were previously unattainable, further enhancing the capabilities of precision manufacturing.

Efficient manufacturing in precision casting brings significant advantages, particularly through the implementation of advanced technologies and methods such as EGR SS (Enhanced Green Remelt Stainless Steel). According to a report by Smith & Associates, precision casting accounts for nearly 25% of the global casting market, which was valued at approximately $125 billion in 2022. This shift towards precision techniques not only optimizes production efficiency but also reduces waste, preserving material integrity and minimizing energy consumption by up to 30%.

One of the key benefits of efficient manufacturing in precision casting lies in the improvement of product quality. A study conducted by the International Journal of Precision Engineering indicated that companies adopting advanced casting technologies experienced a 40% reduction in defects. This not only enhances customer satisfaction but also contributes to long-term cost savings. Moreover, efficient manufacturing processes enable quicker turnarounds and increased production speeds, allowing manufacturers to respond swiftly to market demands and maintain a competitive edge in a fast-paced industry. By investing in these advanced precision casting techniques, businesses are better equipped to navigate the complexities of modern manufacturing.

Innovative developments in EGR SS precision casting are paving the way for more efficient manufacturing processes in various industries. The shift towards advanced casting techniques has become essential as businesses strive for greater accuracy and lower production costs. According to recent industry reports, the global precision casting market is expected to reach $58 billion by 2027, growing at a CAGR of 7.3%. This trend highlights the increasing reliance on these innovative technologies to meet the demands of modern manufacturing.

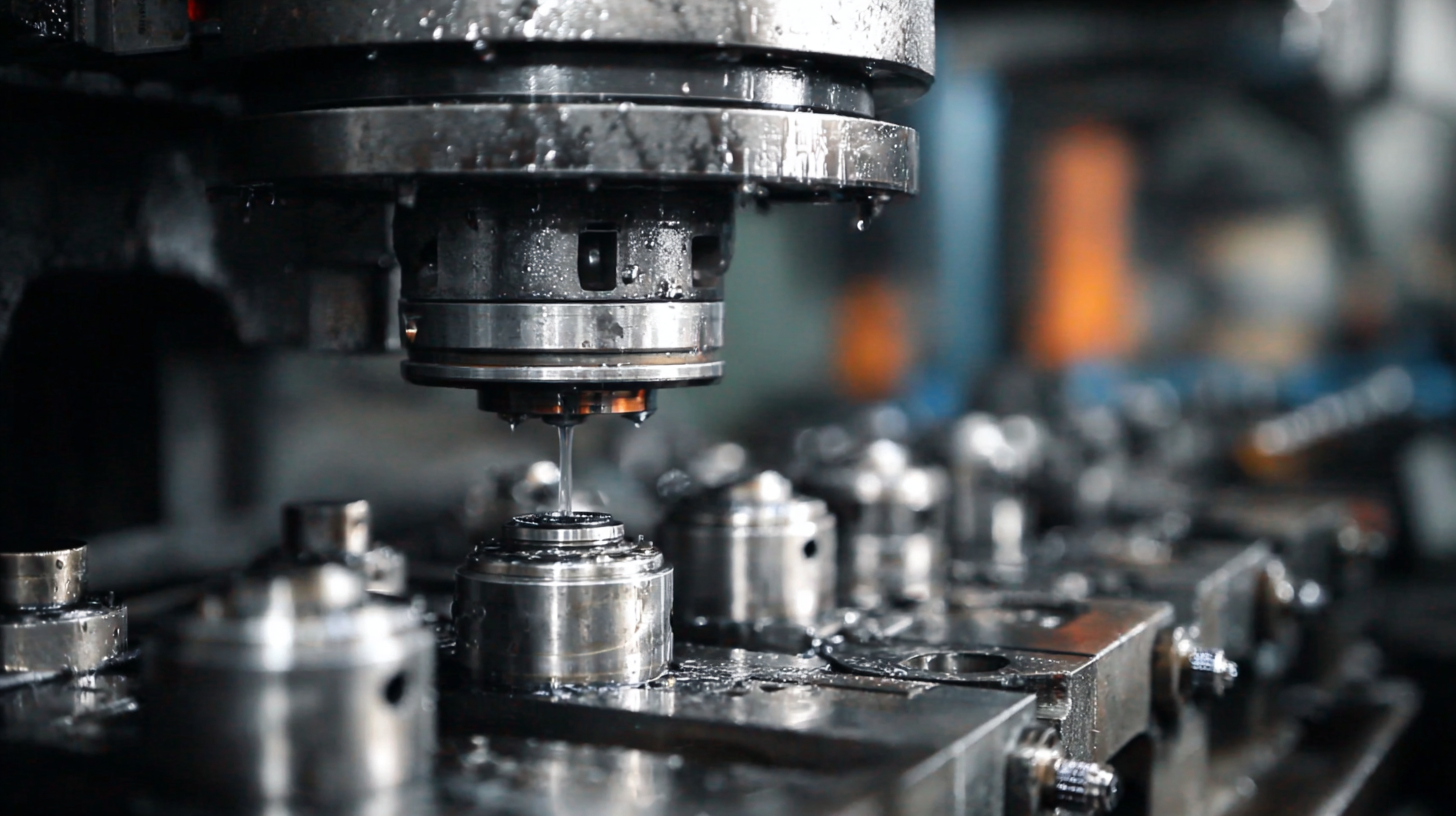

As manufacturers adopt EGR SS precision casting, they benefit from improved dimensional accuracy and surface finish, which are crucial for high-performance applications. This casting technique reduces material waste and energy consumption, aligning with sustainable manufacturing practices that are becoming increasingly important. A report by a leading market research firm indicates that companies implementing advanced casting solutions can reduce lead times by upwards of 30%, thus enhancing overall productivity. Such efficiencies are vital in today’s competitive landscape where every second and every dollar counts.

Choosing the right casting technique is crucial for manufacturers aiming to optimize production efficiency while meeting specific product requirements. Among the various precision casting techniques, lost wax casting, sand casting, and investment casting each offer distinct advantages depending on the complexity and volume of the parts being produced. For instance, lost wax casting is ideal for intricate designs and tight tolerances, making it a preferred choice for industries requiring high precision, such as aerospace and medical devices.

On the other hand, sand casting is more suitable for larger parts and lower volume production runs, offering flexibility and cost-effectiveness. This technique allows for the quick production of molds and can accommodate a wide range of metals, making it a versatile option for many manufacturers. Investment casting, while similar to lost wax casting, provides excellent surface finishes and can handle complex geometries, making it ideal for specialized components in automotive and industrial applications. By carefully evaluating the specific needs of the product, manufacturers can select the casting technique that will not only ensure quality but also enhance overall efficiency in the production process.

This chart compares the efficiency of various casting techniques used in manufacturing specific product needs.