In the realm of aerospace engineering, the demand for materials that offer both strength and lightweight properties is paramount.

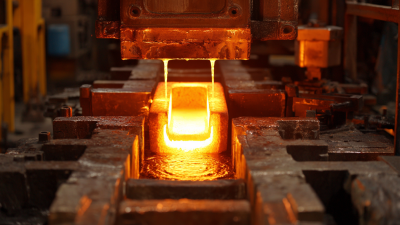

Copper Precision Casting has emerged as a vital technique in addressing these challenges, enabling the production of intricate components that meet stringent performance standards. This process not only optimizes the mechanical properties of copper but also allows for high levels of detail and accuracy in manufacturing, which is essential for aerospace applications.

By delving into the techniques and innovations behind Copper Precision Casting, we can unlock the potential of this versatile material, paving the way for advancements in aerospace design and functionality.

As the industry continues to evolve, understanding the intricacies of this casting method becomes crucial for engineers and manufacturers looking to enhance performance while maintaining cost-effectiveness and sustainability.

Copper Precision Casting has emerged as a vital technique in addressing these challenges, enabling the production of intricate components that meet stringent performance standards. This process not only optimizes the mechanical properties of copper but also allows for high levels of detail and accuracy in manufacturing, which is essential for aerospace applications.

By delving into the techniques and innovations behind Copper Precision Casting, we can unlock the potential of this versatile material, paving the way for advancements in aerospace design and functionality.

As the industry continues to evolve, understanding the intricacies of this casting method becomes crucial for engineers and manufacturers looking to enhance performance while maintaining cost-effectiveness and sustainability.

The aerospace industry is increasingly recognizing the significance of copper precision casting, a technique that offers superior mechanical properties and thermal conductivity essential for high-performance components. According to a recent report by Grand View Research, the global aerospace casting market is projected to reach approximately $16 billion by 2025, with copper alloys playing a pivotal role in this growth. Copper's natural resistance to corrosion and high electrical conductivity make it an ideal choice for critical aerospace applications, including electrical connectors and heat exchangers.

Furthermore, the demand for lightweight and efficient materials in aerospace is driving innovations in copper precision casting methods. The American Foundry Society highlighted that precision castings can reduce weight by up to 50% compared to traditional manufacturing methods, ultimately enhancing fuel efficiency and decreasing emissions. As aerospace manufacturers seek to comply with stringent environmental regulations, the adoption of advanced copper casting techniques not only optimizes performance but also contributes to sustainability goals within the industry.

Copper alloys have become increasingly important in the aerospace industry due to their unique properties that enhance the performance of lightweight components. The benefits of using copper in aerospace applications include high thermal and electrical conductivity, excellent corrosion resistance, and impressive strength-to-weight ratios. According to reports, the demand for specialized metal powders, including copper alloys, is expected to rise significantly, driven by advancements in additive manufacturing and the need for more efficient materials in aerospace applications.

Copper alloys have become increasingly important in the aerospace industry due to their unique properties that enhance the performance of lightweight components. The benefits of using copper in aerospace applications include high thermal and electrical conductivity, excellent corrosion resistance, and impressive strength-to-weight ratios. According to reports, the demand for specialized metal powders, including copper alloys, is expected to rise significantly, driven by advancements in additive manufacturing and the need for more efficient materials in aerospace applications.

Furthermore, the lightweight nature of copper alloys reduces overall aircraft weight, leading to improved fuel efficiency and operational costs. For instance, the use of advanced copper alloys can result in a weight reduction of up to 15% compared to traditional materials. Additionally, the growing trend towards sustainable aviation solutions points to a future where copper precision casting plays a pivotal role in developing components that meet rigorous safety and environmental standards. With ongoing innovation and investment in copper alloy technologies, the aerospace sector is poised to unlock new potentials while harnessing the inherent advantages of these materials.

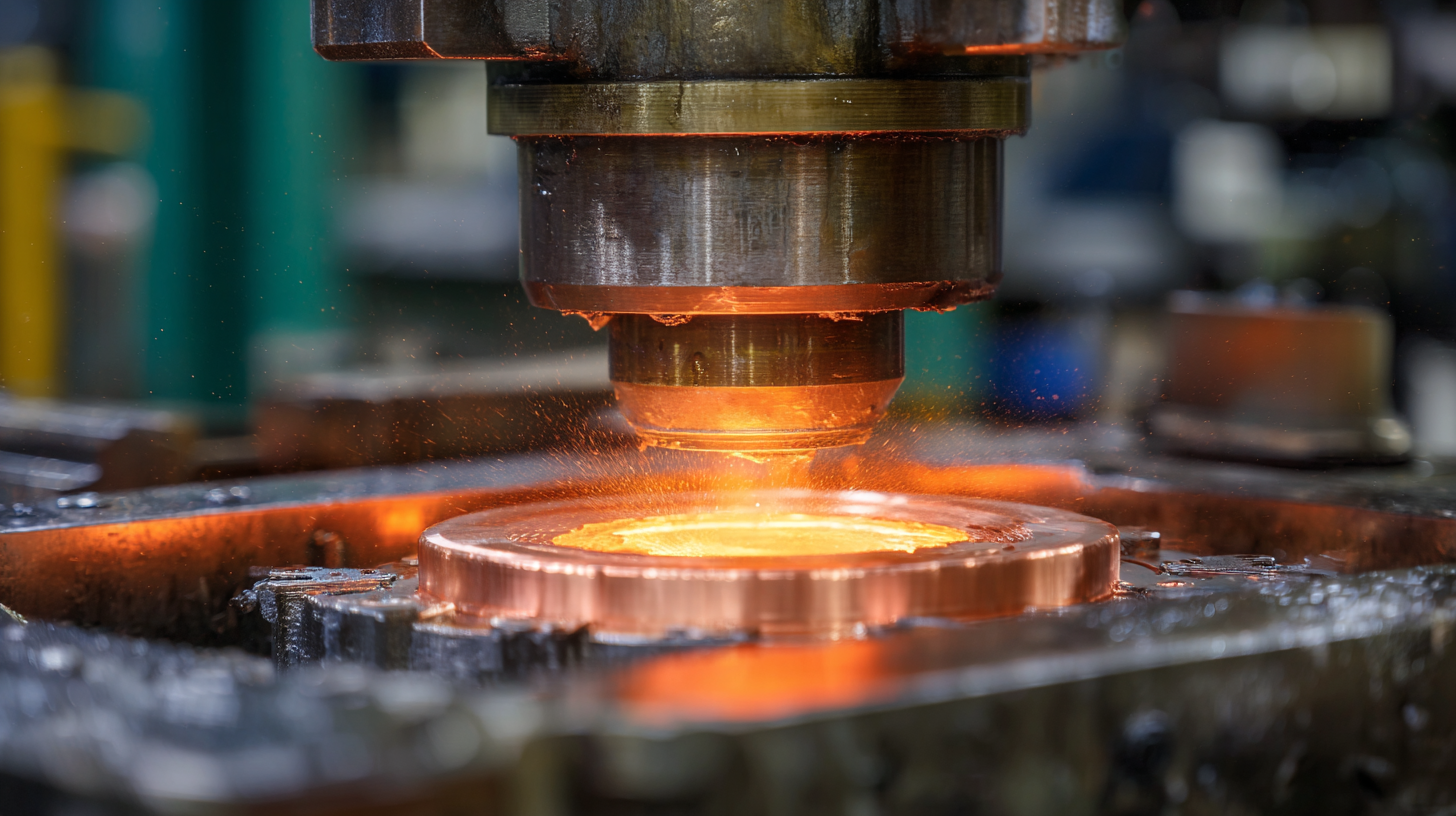

Key innovations in copper casting techniques are paving the way for enhanced performance in aerospace applications. The aerospace industry demands materials that exhibit high strength-to-weight ratios and excellent thermal conductivity. By harnessing advanced casting methods, such as vacuum casting and lost-wax techniques, manufacturers can produce intricate copper components that are not only lighter but also exhibit superior durability. These innovations allow for tighter tolerances and improved surface finishes, which are crucial for components that operate in extreme environments.

Moreover, the integration of alloying elements and refined melting processes has led to the development of copper alloys specifically tailored for aerospace use. These new materials offer enhanced resistance to thermal fatigue and oxidative wear, extending the lifespan of critical components like heat exchangers and electrical connectors. By exploring these advancements in copper precision casting, aerospace engineers can achieve higher efficiency and reliability, thus better meeting the rigorous demands of modern aviation technology.

The aerospace industry is witnessing a significant surge in demand for copper-casted components. This growth can be attributed to the material's excellent electrical conductivity, corrosion resistance, and thermal properties, making it ideal for high-performance applications. With advancements in casting technologies, manufacturers are now able to produce intricate geometries and lightweight designs that are crucial for modern aircraft and spacecraft. As a result, the market for copper precision casting in aerospace is expected to expand rapidly in the coming years.

When it comes to leveraging the benefits of copper casting, consider these tips for your projects. First, it’s essential to collaborate closely with your casting supplier to optimize the design for manufacturability. This can help reduce lead times and costs associated with complex parts. Second, ensure rigorous testing and quality control processes are in place, as the aerospace sector demands the highest standards of safety and reliability. Finally, stay updated on the latest trends in aluminum-lithium alloys and composites, as these materials might influence your copper-casting strategies in multi-material designs for aerospace applications.

| Year | Market Demand (tons) | Percentage Growth (%) | Applications |

|---|---|---|---|

| 2020 | 3,500 | - | Structural components |

| 2021 | 4,000 | 14.29 | Engine parts |

| 2022 | 4,500 | 12.50 | Electrical connectors |

| 2023 | 5,200 | 15.56 | Hydraulic systems |

| 2024 (Projected) | 6,000 | 15.38 | Control systems |

Copper precision casting has gained traction in aerospace applications due to its superior thermal and electrical conductivity. However, industries face several challenges when adopting this technique. One major hurdle is the high melting point of copper, which complicates the casting process and increases energy costs. Additionally, achieving intricate designs and maintaining dimensional accuracy are critical to meet the strict aerospace standards. To tackle these issues, engineers are exploring advanced casting methods, such as investment casting and die casting, which can enhance precision.

Tips for successful implementation include investing in high-quality mold materials and ensuring optimal cooling rates during the casting process. Regular testing and quality control checks can help detect defects early and ensure that the final products meet rigorous ISO standards. Furthermore, collaboration with experienced foundries specializing in copper materials can provide insights into best practices and innovative solutions tailored to specific aerospace needs. Emphasizing continuous training for personnel involved in the casting process can also facilitate smoother transitions and reduce the learning curve associated with new techniques.