Choosing the right Precision Casting Components is crucial for many applications. These components are often used in automotive, aerospace, and industrial sectors. They must meet specific requirements to perform effectively.

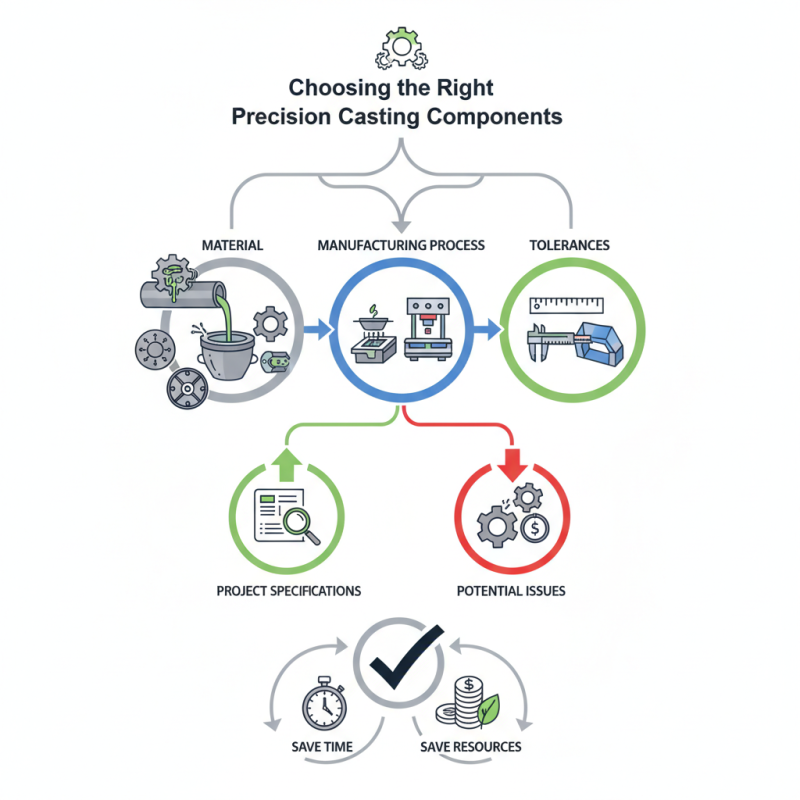

Precision casting allows for intricate designs with high dimensional accuracy. However, with many options available, selecting the ideal component can be overwhelming. Consider the material, manufacturing process, and tolerances required for your project.

Not every casting method suits every need. It's essential to reflect on your project specifications. While one method might work well, it can lead to issues in another application. Take the time to understand your requirements fully. Doing so can save time and resources down the line.

Precision casting is an advanced manufacturing process that creates complex metal components with high accuracy. It is widely used across industries such as aerospace, automotive, and medical. Research indicates that the global precision casting market is projected to grow significantly, reaching over $35 billion by 2025. This growth stems from the increasing demand for lightweight, durable materials that can withstand extreme conditions.

When selecting precision casting components, consider factors like material type and design specifications. Certain alloys, such as stainless steel or aluminum, offer unique benefits for different applications. Ensure that the component can endure the required stresses in real-world usage. Pay attention to surface finish and dimensional tolerances, as these can dramatically affect performance. Also, look out for application-specific requirements that might not be immediately clear.

**Tip:** Always request prototypes and test samples. This helps validate design choices before committing to large orders. Ensure open communication with manufacturers. Clarity in expectations can avoid costly revisions later. Misunderstandings can lead to subpar components. Reflect on your needs carefully to avoid oversights. Quality shouldn’t be sacrificed for speed.

When selecting precision casting components, material choice is crucial. The right casting material directly affects the component's strength and durability. Various materials, such as aluminum, steel, and bronze, each have unique properties. For example, aluminum is lightweight yet strong, while steel offers superior durability. Understanding these properties helps in making an informed decision.

Consider your specific application. Will the component be exposed to high temperatures? If so, certain materials might degrade faster than others. Evaluate the operating environment, including potential corrosion factors. Not all metals handle environmental stress equally. It’s essential to match the material's characteristics with your project needs.

Think about cost-effectiveness, but don’t compromise quality. Cheaper materials may seem attractive but can lead to failure down the line. Always weigh the long-term benefits against short-term savings. Gathering feedback from engineers or consulting experts can provide valuable insight. Reflection on previous experiences can guide future choices. Material selection is often an iterative process, so stay open to adjustments as you gather more information.

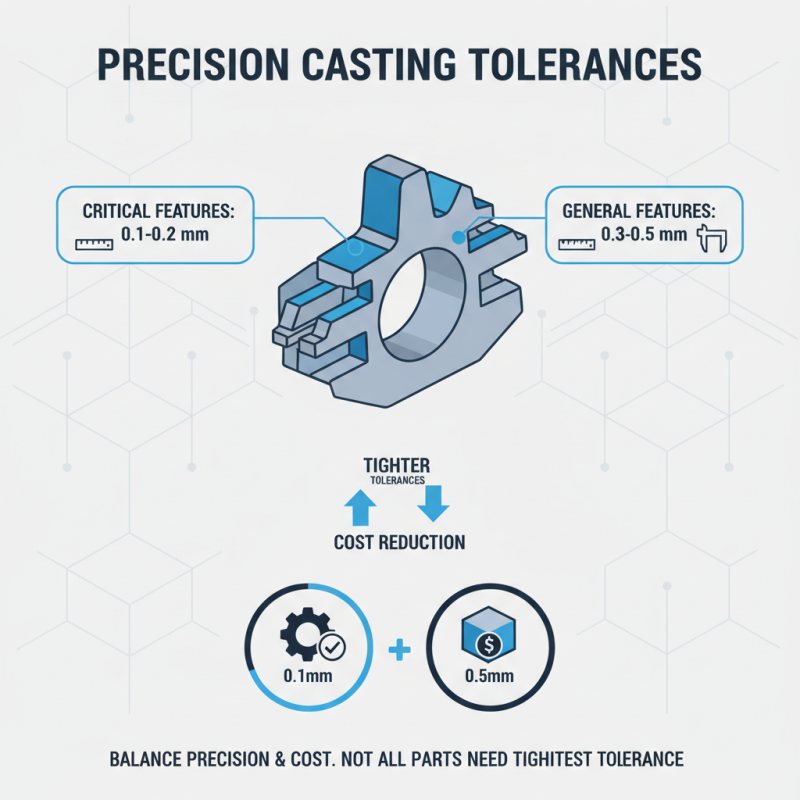

When evaluating design specifications for precision casting components, key factors must be considered. Tolerance levels are crucial. They can range from 0.1 mm to 0.5 mm based on the part’s function. Precision casting often achieves tighter tolerances than traditional methods, yet not all projects require such specifications. For many components, a less rigid tolerance may suffice, reducing overall costs.

Material selection is another critical aspect. For instance, aluminum is lightweight but less durable. Steel, while heavier, offers superior strength. A report by the Precision Casting Association highlights that about 70% of manufacturers prefer alloy-based materials for their excellent finish and durability. However, companies sometimes overlook environmental factors, potentially leading to increased waste and emissions. Balancing these specifications is essential, yet many still struggle with mismatched priorities.

Lastly, design complexity can impact manufacturability. The more intricate a design, the higher the chances of defects. A 2023 industry study found that nearly 40% of precision castings fail quality checks due to complexity issues. Simplifying designs can enhance production efficiency. Still, there is a fine line between simplicity and functionality, which often leads to ongoing debates among engineers. As precision casting evolves, continuous reassessment of design specifications is necessary to optimize outcomes.

When selecting precision casting components, it's crucial to assess the manufacturer's capabilities. Look for facilities equipped with modern technology. Advanced equipment often leads to better quality. A manufacturer should be able to demonstrate their proficiency in various casting processes. This includes sand casting, investment casting, and die casting. Ensure they have experienced technicians who can oversee production.

Quality standards are equally important. Check if the manufacturer follows internationally recognized guidelines. ISO certifications are a good indicator of commitment to quality. Ask about their quality control processes. It should involve regular inspections, testing, and documentation. Sometimes, a manufacturer may present impressive credentials but lack effective execution. Be cautious. A visit to their facility can reveal practical insights into their operations.

Lastly, communication matters. A responsive manufacturer will quickly address your concerns. This reflects their dedication to customer satisfaction. A lack of clear communication may pose future challenges. Trust your instincts as you evaluate potential partners. It's essential to ensure you choose a manufacturer that aligns with your quality expectations and production needs.

| Manufacturer | Capabilities | Quality Standards | Materials Offered | Lead Time | COC Availability |

|---|---|---|---|---|---|

| Manufacturer A | Sand Casting, Investment Casting | ISO 9001, AS9100 | Aluminum, Steel, Brass | 3-4 Weeks | Yes |

| Manufacturer B | Die Casting, Lost Foam Casting | ISO 14001 | Stainless Steel, Copper | 2-3 Weeks | Yes |

| Manufacturer C | Investment Casting, Precision Machining | ISO 9001, ISO/TS 16949 | Titanium, Aluminum | 4-6 Weeks | No |

| Manufacturer D | Sand Casting, Lost Wax Casting | ISO 9001 | Bronze, Steel | 5-7 Weeks | Yes |

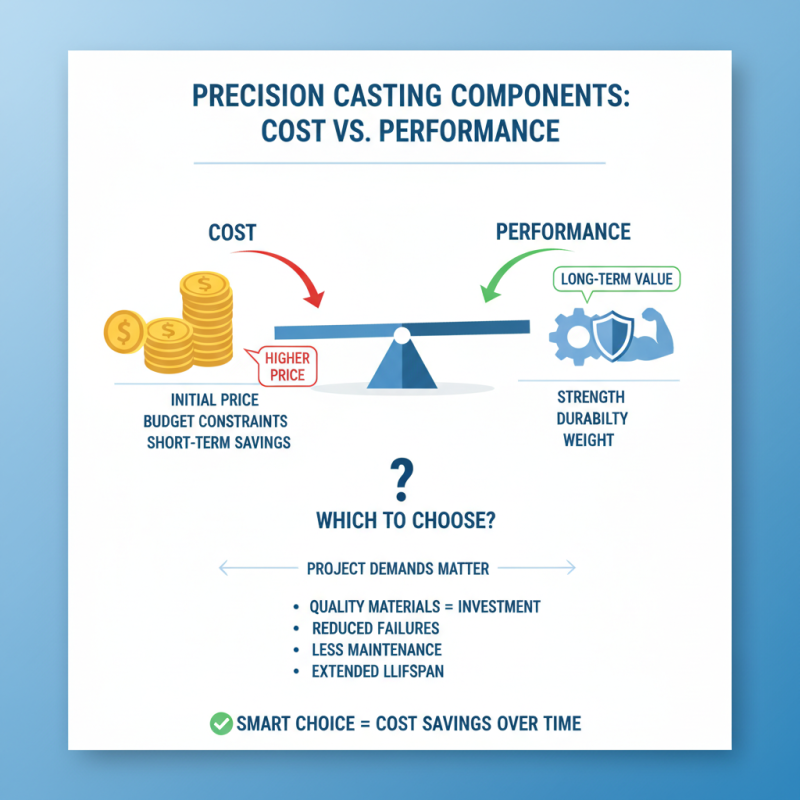

When selecting precision casting components, cost and performance often clash. Quality components may come with a higher price tag. However, investing in better materials may save costs in the long run. Consider the specific demands of your project. Performance metrics like strength, durability, and weight play a crucial role.

You might find lower-priced options tempting. Yet these can compromise quality. A weak component can lead to failures. This might result in costly repairs or even project delays. It’s worth weighing the pros and cons carefully.

Think about your project's lifecycle. Cheaper components often wear out faster, increasing replacement frequency. Performance should not be overlooked. Aim for a balance that suits your budget. Many overlook the long-term implications of their choices. Reflect on what matters most: upfront savings or reliable performance over time.