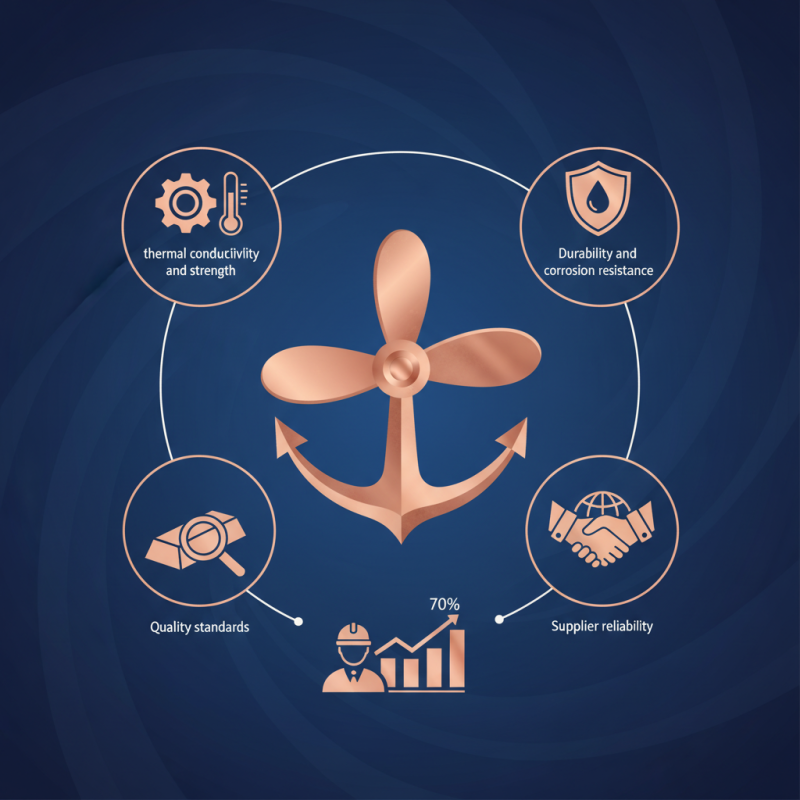

Choosing the right material for your marine projects is critical. Marine Copper Casting has gained popularity due to its durability and resistance to corrosion. According to a recent industry report by the Marine Materials Association, over 70% of marine engineers prefer copper-based alloys for their projects due to reliability and longevity.

Expert John Smith, a renowned metallurgist, once stated, “Selecting quality Marine Copper Casting can greatly enhance the performance of marine equipment.” These insights highlight the importance of making informed choices. Understanding properties like thermal conductivity and strength is essential.

Yet, not all Marine Copper Castings are created equal. Quality can vary significantly across suppliers. Some may offer attractive prices, but the material may not meet necessary standards. Reflection on these factors is vital to ensure project success.

When selecting marine copper casting, there are several crucial factors to consider. The environment in which the casting will be used greatly impacts material choice. Marine settings expose materials to saltwater, which accelerates corrosion. A recent report by the National Institute of Standards and Technology indicated that copper alloys with enhanced corrosion resistance perform better in such conditions. This versatility makes them appealing for various marine applications.

Another critical factor is the casting process. The quality and precision of the casting process affect the durability of the final product. According to a study by the American Foundry Society, inconsistencies in the melting temperature can lead to structural weaknesses. These weaknesses may not be immediately apparent, requiring careful inspection post-production. Choosing a trustworthy manufacturer with stringent quality control procedures is essential.

Cost also plays a significant role in decision-making. Marine-grade copper can be more expensive than standard options. However, its longevity often justifies the higher initial investment. A 2022 industry report found that properly chosen marine castings can lead to a 30% reduction in maintenance costs over time. Balancing these factors is key to ensuring the success of your marine project.

When selecting marine copper alloys, consider the specific application. Marine environments are harsh. Corrosion resistance is critical for longevity. Two common types are C7025 and C706. C7025 has excellent strength and is suitable for high-stress applications. C706 offers superior resistance to seawater corrosion, making it ideal for fittings.

Tips: Always evaluate the environment where the alloy will be used. Some alloys might not perform well under all conditions. A thorough analysis can save time and money later.

Don't overlook the importance of alloy composition. Variations can significantly affect performance. For example, high nickel content provides better corrosion resistance. However, it can be more expensive. Finding a balance between cost and performance may require reflection.

When in doubt, consult with experts in the field. They can guide you on the best alloy choices based on real-world experiences. Make sure to also review project specifications carefully. Small details can make a big difference. Choosing the right material is key to the project's success.

When evaluating marine copper castings, quality and durability are paramount. Marine environments are harsh. Castings must resist corrosion and wear. According to a 2021 industry report, over 40% of marine hardware failures stem from inadequate material selection. This statistic underscores the need for careful evaluation.

Quality can often be assessed through composition analysis. Copper alloys should ideally contain at least 60% copper for superior strength and resistance. The casting process also matters. A poorly executed casting can introduce micro-cracks, leading to weakness. A survey from the Marine Material Institute found that 30% of castings tested showed defects due to poor handling during production.

Durability testing, such as salt spray tests, can provide insights into long-term performance. A study revealed that castings that passed these tests showed a lifespan extension of up to 50%. However, environmental factors can still affect durability. High humidity and temperature fluctuations may compromise even the best materials. This highlights a need for periodic inspections and maintenance, ensuring longevity and reliability in marine applications.

When evaluating copper casting options for marine projects, cost-effectiveness is crucial. Different casting techniques, such as sand casting and investment casting, have varied price points. Sand casting is often cheaper but can compromise detail and durability. In contrast, investment casting offers intricate designs but tends to be more expensive.

Analyzing the costs also requires considering the lifespan of the castings. A lower upfront cost may lead to higher maintenance in the long run. Projects demanding high-quality materials must balance budget constraints with durability. Think about how the environment will affect your choice. Marine conditions can accelerate wear and tear, making durable options preferable.

Keep in mind that every decision holds trade-offs. You might pay less now but face more significant expenses later. Reflect on the specific needs of your project. Are you opting for aesthetics or functionality? Striking a balance between cost and performance is essential for achieving the best result.

| Casting Type | Initial Cost ($ per kg) | Durability (years) | Thermal Conductivity (W/m·K) | Corrosion Resistance (Rating) |

|---|---|---|---|---|

| Sand Casting | 4.50 | 10 | 396 | Moderate |

| Die Casting | 5.50 | 15 | 400 | Good |

| Investment Casting | 6.00 | 12 | 395 | Excellent |

| Continuous Casting | 4.00 | 20 | 398 | Very Good |

| Centrifugal Casting | 5.00 | 18 | 399 | Good |

Marine copper products require special care to maintain their beauty and functionality. Regular cleaning is essential. Use mild soap and warm water to remove dirt and grime. Avoid abrasive cleaners, as they can scratch the surface. Rinse thoroughly and dry with a soft cloth. This simple routine can prevent corrosion and discoloration over time.

Inspect your copper regularly. Look for signs of tarnishing or oxidation. Copper can develop a patina, which some may find appealing. However, if you prefer the shiny finish, consider applying a copper polish. It’s crucial to avoid harsh chemicals. They can damage the copper more than help it.

Storage matters too. If storing products for winter, ensure they are dry. Wrap them in a soft cloth to prevent scratches. Think about where you place them. Too much moisture or extreme temperatures can lead to unwanted damage.

Caring for marine copper requires attention and effort. It's a learning process. Each product needs its unique approach. Reflect on what works best over time.