Choosing the right Electrical Copper Castings is crucial for any engineering project. Expert John Smith, a renowned figure in the electrical industry, emphasizes, "Quality castings lead to better performance in electrical systems." This insight highlights the need for careful consideration during selection.

Electrical Copper Castings come in various forms, each with distinct applications. From connectors to busbars, the choice depends on project specifications. Factors like conductivity, durability, and cost play significant roles. A mismatched selection can lead to failures, increasing project costs and delays.

Many overlook the importance of quality in Electrical Copper Castings. It's tempting to go for the cheapest option. However, this can result in poor performance and safety issues. Engineers must balance cost and quality. Reflecting on past projects can guide better decision-making. Ultimately, a thoughtful approach leads to superior outcomes.

Electrical copper castings play a vital role in many projects. Knowing the basics can help you make informed choices. Copper is known for its excellent conductivity. This makes it suitable for electrical applications. Castings can vary widely in specifications and Quality. It’s essential to understand your project’s requirements.

When selecting copper castings, consider the alloy composition. Different alloys can affect performance. Pay attention to the casting method as well. Techniques like sand casting and die casting produce different results. Make sure you align your choice with your project's specific needs.

Tips: Always check for consistent quality. Inconsistent quality can lead to failures. Look for detailed specifications and manufacturing standards. Discuss your needs with suppliers. They can guide you to the right options. Remember, the right casting can make all the difference. Don’t rush your decisions; take the time to compare.

| Casting Type | Conductivity (%) | Melting Point (°C) | Applications | Cost ($/kg) |

|---|---|---|---|---|

| C11000 | 100 | 1083 | Electrical wiring, connectors | 6.00 |

| C14500 | 96 | 1083 | Motor components, transformers | 7.50 |

| C19700 | 93 | 1090 | Bus bars, electrical components | 8.25 |

| C38000 | 86 | 1030 | Electrical contacts, buttons | 9.00 |

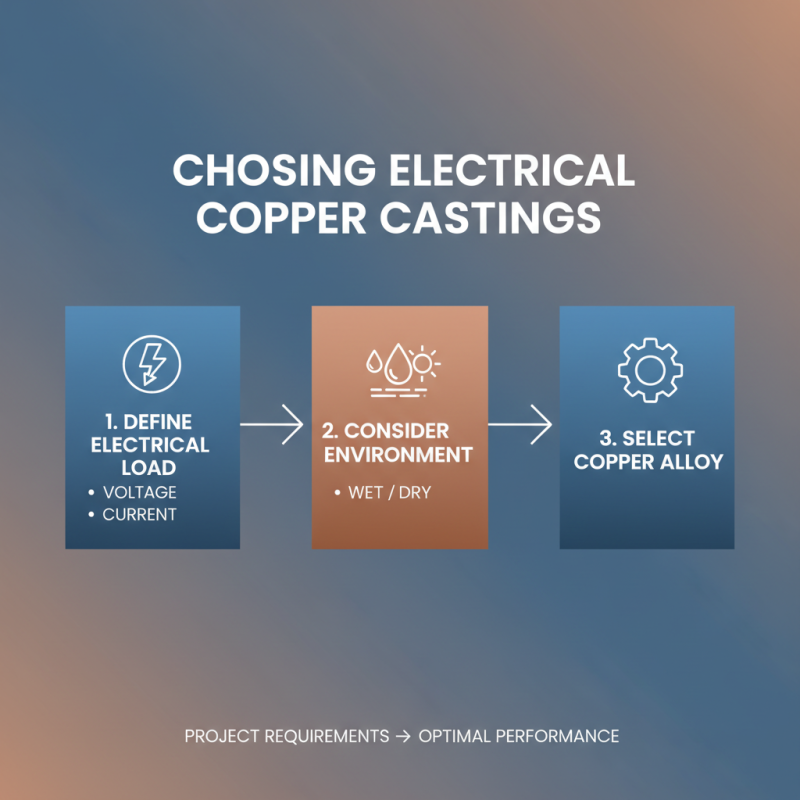

Choosing the right electrical copper castings begins with understanding your project's specific requirements. Start by defining the electrical load needs. Consider factors like voltage and current. Determine if the environment is wet or dry. Such details influence the type of copper alloy suitable for your casting.

Next, assess the dimensions and shape needed for your project. Custom sizes may be necessary, which can complicate the process. Think about whether the castings need intricate designs or can be basic. This requirement will significantly impact the manufacturing method.

Lastly, reflect on the finish required. Will a smooth surface suffice, or is enhanced conductivity essential? Sometimes, opting for a less polished finish may save time and cost. This could affect performance, so weigh the pros and cons carefully. Choices here can lead to unexpected challenges in later stages of your project.

When evaluating the quality standards for electrical copper castings, several factors come into play. The purity of the copper is crucial. High purity ensures better conductivity and durability. Look for castings that specify at least 99% copper content. This is a basic requirement for many electrical applications.

Inspecting the casting process is equally important. Different methods create varying surface finishes and internal structures. Castings made through die casting can offer better precision than sand casting. However, sand castings often have better stress resistance. Choose the method that aligns with your project’s needs.

Don’t overlook the importance of testing and certifications. Finding a supplier who adheres to relevant industry standards can be challenging. Always ask for reports on mechanical properties and electrical performance. Sometimes suppliers may not provide all the necessary information upfront. Be prepared to dig deeper or request additional data. An informed choice is the best basis for any successful project.

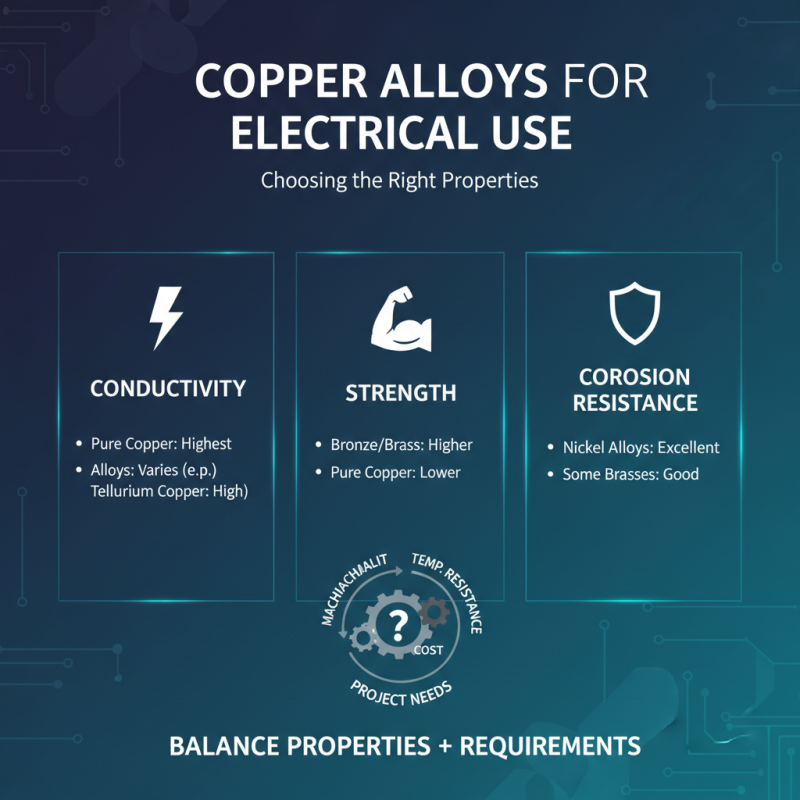

When selecting copper alloys for electrical applications, understanding their properties is crucial. Copper alloys vary significantly in terms of conductivity, strength, and resistance to corrosion. For example, tellurium copper offers excellent machinability and conductivity but may not withstand high temperatures. It’s vital to weigh these factors against your project requirements.

Another common option is beryllium copper. While this alloy provides superior strength and conductivity, it’s also more expensive and can be toxic during processing. Consider the safety measures needed if you choose this material. On the other hand, brass, a copper-zinc alloy, is less conductive but provides good wear resistance. If your project involves mechanical parts, brass may be a more practical choice.

Many users overlook the importance of thermal properties as well. Some alloys have a high thermal conductivity, essential for heat dissipation in electrical components. Others can perform poorly under specific conditions. Make sure to evaluate how your chosen alloy will react to heat and environmental factors. Different projects demand different properties; reflect on your specific needs to choose the right alloy.

Budgeting for electrical copper castings involves several key factors. The cost of raw materials can fluctuate, impacting your overall budget significantly. Ensure you research current copper prices. Be aware of market trends that could affect your procurement.

Next, consider the complexity of your design. Intricate patterns often mean higher production costs. Simplifying your design may save money. However, avoid sacrificing quality for budget. Always evaluate whether the cheaper option meets your project's needs.

Balancing cost with performance is crucial. Finally, factor in additional expenses. This includes labor and transportation costs. Sometimes, these hidden costs can surprise you. Keep them in mind while planning. Reflecting on these aspects will help you make informed decisions. Stay flexible to adjust your budget as needed.