Steel Investment Casting has emerged as a critical manufacturing process in various industries. This method involves creating precise metal parts from liquid steel, allowing for exceptional detail and complexity. In 2026, advancements in techniques are reshaping the landscape of steel investment casting.

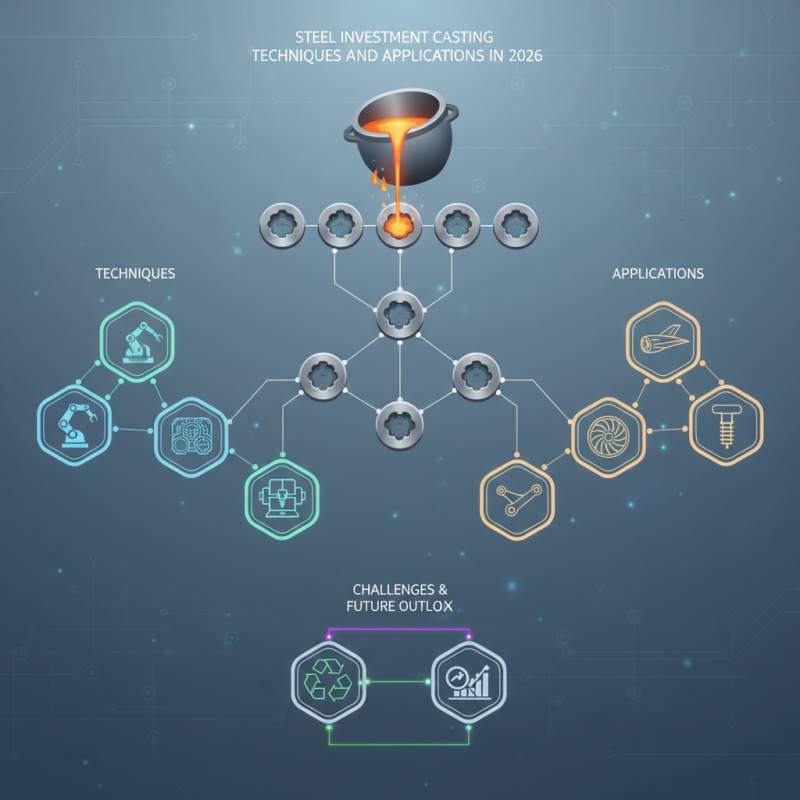

Innovative applications are broadening the scope of where steel investment casting excels. From aerospace components to automotive parts, industries benefit from this technology. The strength and durability of steel provide significant advantages. However, challenges persist. Not every technique achieves the same level of efficiency or accuracy. It raises questions about material selection and cost-effectiveness.

As we explore the best steel investment casting techniques of 2026, we confront ongoing dilemmas. Are current methods sustainable? How can we minimize waste? These considerations are vital for progress. Reflecting on these issues will drive improvements in the steel investment casting industry.

Steel investment casting is a precise technique known for producing intricate shapes. This method allows for high dimensional accuracy and smooth surface finishes. It is widely used in industries such as aerospace and automotive. The process involves creating a wax model, encasing it in ceramic, and then melting out the wax to form a cavity for steel.

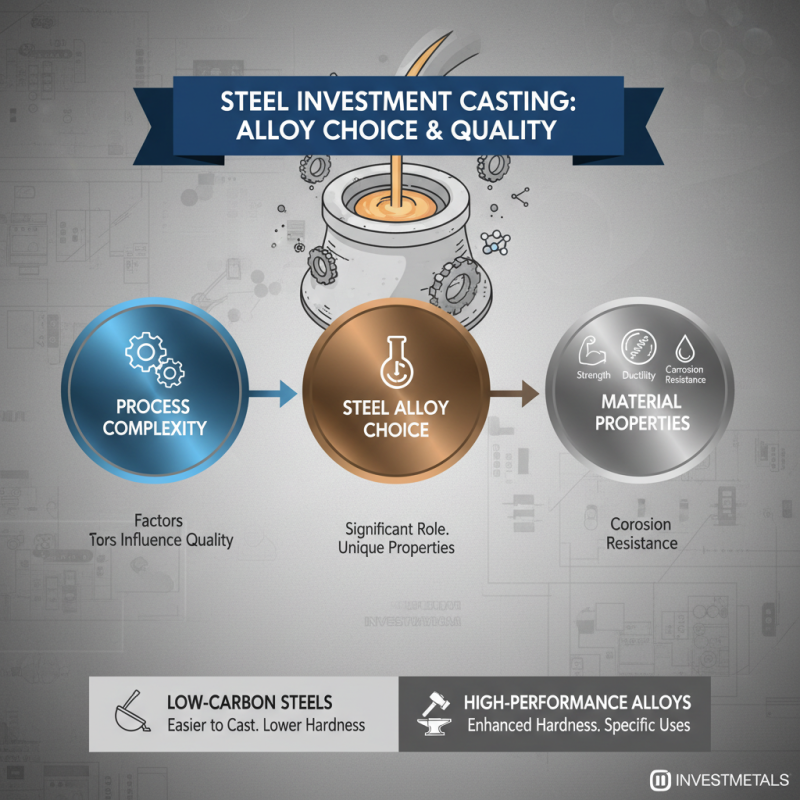

When selecting the right technique, consider the type of steel needed. Different alloys offer varying strength, corrosion resistance, and machinability. Tip: Always consult with engineers to match steel grades with project requirements. The right choice impacts durability and performance.

Another crucial aspect is the quality of the pattern. Imperfections in the original design can lead to defects in the final product. Tip: Regularly review patterns for accuracy. Small errors can snowball into significant issues during production. Effective communication with design teams can help identify potential problems early on. Combining these elements ensures success in steel investment casting projects.

Steel investment casting is a complex process. Various factors influence its quality. The choice of steel alloy plays a significant role. Each alloy has unique properties affecting strength, ductility, and resistance to corrosion. For instance, low-carbon steels are easier to cast but may not offer the desired hardness.

Another critical factor is the design of the casting itself. Intricate designs can lead to issues such as poor surface finish or incomplete fills. Simplicity often aids in achieving better results. Temperature control during the pouring process is also essential. If the metal is too hot, it may cause defects like oxidation. Cooling rates can affect the final microstructure of the material.

Finally, inspection and testing methods are crucial for quality assurance. Without thorough checking, defects can go unnoticed. This can lead to colossal failures in applications. Regular feedback loops in the production process help in identifying issues early. Reflection on these factors is vital for improvement. By addressing these areas, the quality of steel investment casting can significantly increase.

Steel investment casting is increasingly popular in various industries. Research indicates that the aerospace sector alone accounts for over 30% of investment casting applications. This process produces complex geometries that meet stringent quality standards. For example, intricate components like turbine blades and housings are manufactured using this technique. Aerospace parts often require high strength and lightweight solutions, which steel investment casting provides effectively.

In the automotive industry, steel investment casting is vital for manufacturing critical components. Components like gears, valve bodies, and pump housings benefit from precise dimensions and robust properties. The automotive sector aims for a lightweight yet durable design to improve fuel efficiency and reduce emissions. Reports show that automotive manufacturers are shifting towards higher-quality castings to enhance vehicle performance.

Healthcare also embraces steel investment casting. Surgical instruments and implantable devices utilize this technique for their reliability and precision. Industry data reveals that the healthcare sector is growing at a significant rate. Nonetheless, challenges remain, such as ensuring production consistency. Quality control is crucial in maintaining the standards expected in medical applications. Improving these processes involves ongoing industry reflection and technological advancement. As industries evolve, so will the applications of steel investment casting.

Steel investment casting has seen remarkable innovations in recent years. New techniques are streamlining production processes. These advancements enhance precision and reduce waste. As a result, manufacturers can produce complex shapes with tighter tolerances. This opens doors for various industries, from automotive to aerospace.

One notable trend is the integration of digital technologies. 3D modeling software allows for better design validation. It helps in creating molds that are more accurate. However, some challenges remain. The transition to these technologies can be slow and costly. Many manufacturers struggle to adapt. Additionally, not all innovations yield immediate results.

Sustainability is another focus area. Processes that reduce emissions and energy consumption are in demand. Yet, implementing these techniques requires thorough planning. Simply adopting new methods without proper evaluation can lead to inefficiencies. Balancing innovation with practical execution is crucial for long-term success.

| Technique | Application | Material Type | Advantages | Challenges |

|---|---|---|---|---|

| Lost Wax Casting | Aerospace Components | Carbon Steel | High precision and surface finish | Long production cycles |

| Shell Molding | Automotive Parts | Alloy Steel | Faster production speed | Limited to smaller parts |

| Investment Casting | Medical Devices | Stainless Steel | Highly intricate shapes | High material costs |

| Die Casting | Industrial Equipment | Tool Steel | Good dimensional accuracy | Limited to thinner sections |

| 3D Printing in Casting | Prototype Development | Various Steel Alloys | Rapid prototyping | Surface finish issues |

Steel investment casting is an important process. However, it can have environmental impacts that need our attention. The traditional methods often produce waste and emissions. This raises questions about sustainability. The industry must evolve.

Recycling materials is one way to reduce waste. Using recycled steel can lessen the carbon footprint. Proper waste management systems must also be in place. They ensure that by-products do not harm our environment. The challenge lies in implementing these practices effectively.

Furthermore, energy consumption during casting processes is a concern. High temperatures require significant energy. Innovations in technology could help here. For instance, using alternative energy sources is a potential solution. Ultimately, the industry must balance efficiency and environmental responsibility. There is room for improvement, and consistent efforts are essential.