In the ever-evolving landscape of manufacturing, the significance of Precision Investment Casting cannot be overstated. As industries increasingly demand complex geometries and high-performance components, investment casting has emerged as a preferred fabrication method. According to a report by Grand View Research, the global investment casting market is projected to reach USD 22.99 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.9%. This growth is driven by the method's ability to produce intricate parts with superior accuracy and minimal waste.

Expert insights further reinforce the value of Precision Investment Casting. Dr. Emily Chen, a leading figure in the field and author of several industry studies, states, "The accuracy and versatility of Precision Investment Casting are not just advantages; they represent a fundamental shift in how components are designed and manufactured." This quote encapsulates the essential role of this casting method in driving innovation across sectors such as aerospace, automotive, and medical devices, allowing manufacturers to meet stringent specifications while maintaining efficiency.

As businesses look to enhance their production capabilities, understanding the ten key benefits of Precision Investment Casting becomes paramount. From reduced lead times to enhanced material properties, these advantages make this manufacturing technique a cornerstone for companies aiming to stay competitive in a rapidly advancing market.

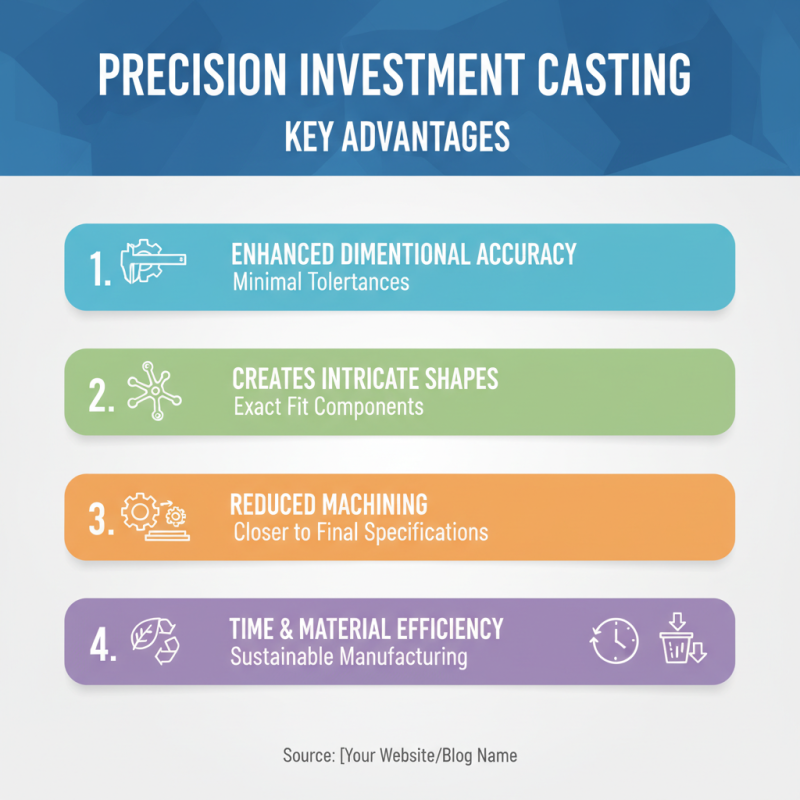

Precision investment casting is renowned for its ability to deliver enhanced dimensional accuracy, a major advantage in various manufacturing applications. This process involves creating intricate shapes with minimal tolerances, which is crucial for components requiring an exact fit or specific performance characteristics. By utilizing wax patterns and high-quality molds, precision investment casting significantly reduces the need for machining, allowing products to be produced closer to their final specifications. This not only saves time but also reduces material waste, making it an efficient choice for manufacturers focused on sustainability.

The enhanced dimensional accuracy achieved through precision investment casting also leads to improved product reliability and performance. Components produced through this method exhibit consistent quality, which is essential in industries where safety and durability are paramount. The ability to produce complex geometries without compromising precision allows engineers to innovate without being restricted by conventional manufacturing methods. Consequently, industries such as aerospace, automotive, and medical benefit immensely from this technology, as it supports the creation of lightweight yet robust parts that meet stringent regulatory standards while maintaining high performance.

Precision investment casting offers significant cost efficiency in production, making it a favored choice among manufacturers. This method allows for complex shapes and intricate designs to be produced with minimal material waste. Unlike traditional casting methods that may require extensive machining and finishing, precision investment casting often requires less post-processing, directly reducing labor costs and production time. The accuracy of the process results in components that require fewer adjustments, translating to a more efficient overall production cycle.

In addition to reducing material and labor costs, precision investment casting can lower inventory expenses. The ability to create precise components in a single-step process minimizes the need for multiple molds and components, enabling manufacturers to consolidate their supply chains. This level of efficiency not only streamlines operations but also results in significant savings over time. As production demand fluctuates, this adaptability ensures that manufacturers can respond swiftly without incurring excessive costs. The economic advantages offered by precision investment casting make it an ideal solution for industries seeking to enhance efficiency while maintaining high-quality standards in their projects.

Precision investment casting has emerged as a pivotal technology in modern manufacturing, particularly due to its ability to significantly reduce material waste. This method utilizes a process where molten metal is poured into a meticulously crafted mold, resulting in high-precision components with minimal excess material. According to a study by the Investment Casting Institute, precision investment casting can achieve material utilization rates exceeding 90%. This efficiency translates into not only cost savings but also a substantial reduction in the environmental footprint associated with material extraction and processing.

The reduction of material waste is crucial in industries where resource conservation is paramount. For instance, sectors like aerospace and automotive have reported that optimizing their casting methods through precision techniques can lower their total material consumption by as much as 30%. This not only streamlines production but also aligns with global sustainability goals. By minimizing scrap metal and rework, manufacturers benefit from reduced costs while contributing to a more sustainable future, showcasing the competitive edge that precision investment casting provides in an increasingly eco-conscious marketplace.

| Benefit | Description | Impact on Material Waste |

|---|---|---|

| High Dimensional Accuracy | Allows for intricate designs with precise tolerances. | Reduces the need for additional machining, thus minimizing waste. |

| Complex Shapes | Can create complex geometries that might be impossible with traditional casting. | Limits scrap material from non-usable designs. |

| Material Versatility | Compatible with a wide range of alloys and metals. | Optimizes material usage based on application needs. |

| Cost Efficiency | Lower production costs at scale due to fewer operations. | Decreases costs associated with wasted materials. |

| Improved Surface Finish | Creates smooth surfaces that often require less finishing. | Minimizes waste from surface preparation processes. |

| High Production Rates | Facilitates fast and efficient mass production. | Reduces overall scrap during rapid production cycles. |

| Enhanced Material Properties | Results in superior mechanical properties due to controlled cooling and solidification. | Leads to less frequent failings and material losses. |

| Reduction of Secondary Operations | Minimizes the need for additional machining or finishing processes. | Lowers waste generated from secondary operations. |

| Sustainability | Efficient use of materials aligns with sustainable practices. | Contributes to reduced environmental impact through lower waste production. |

| Innovative Applications | Facilitates new technologies in aerospace, medical, and automotive industries. | Encourages efficient usage of advanced materials with reduced waste. |

Precision investment casting is renowned for its versatility and broad application range across various industries. This innovative manufacturing process is capable of producing intricate and precise components, making it ideal for sectors such as aerospace, automotive, and medical devices. The ability to cast complex geometries with tight tolerances means that engineers and designers can create components that were once thought impossible with traditional manufacturing methods. This adaptability not only enhances the design freedom but also maximizes efficiency in production, resulting in reduced material waste and lower costs.

When considering precision investment casting for your projects, it’s essential to evaluate the specific requirements of your application. Different materials can be utilized, including metals, alloys, and even ceramics, which offers a tailored solution to meet diverse operational needs.

**Tips:** Always conduct thorough research on the material properties and coatings needed for your specific application. Additionally, engaging with experienced manufacturers can provide insights into optimizing the design for casting processes. Lastly, remember to assess the scalability of your project to ensure that the chosen method can accommodate future growth or modifications efficiently.

Precision investment casting is renowned for its exceptional ability to produce components with superior surface finishes and aesthetic qualities. Unlike traditional casting methods, precision investment casting enables the creation of complex geometries with intricate details, resulting in components that not only perform well but also look exceptional. This process uses a wax pattern that is coated with a ceramic shell, allowing for a smooth surface finish that significantly reduces the need for post-casting machining. Industries such as aerospace, automotive, and medical are increasingly adopting this process for their components, where precision and aesthetics are paramount.

To maximize the aesthetic value of your investment cast components, consider focusing on the mold design. A well-designed mold can enhance the surface finish and alleviate the need for additional finishing processes. Additionally, selecting the right materials for casting is crucial; materials with higher fluidity can result in better surface quality.

Another tip is to collaborate closely with suppliers and engineers during the initial design phase to ensure that your specifications align with the capabilities of the investment casting process. Early identification of design complexities can lead to more effective solutions, saving time and costs while achieving superior visual appeal in the final product. Engaging in this level of detail from the start significantly contributes to the overall success of your casting project.