In the realm of manufacturing, Tin Bronze Precision Casting is gaining significant attention. This process is renowned for its ability to create intricate components with high dimensional accuracy. In 2026, new innovations are transforming how industries utilize tin bronze.

Manufacturers are exploring advanced techniques that enhance durability and reduce waste. These innovations include improved melting processes and sustainable materials. However, challenges remain. The constant evolution in technology demands skilled workers who can adapt to new systems.

Furthermore, the environmental impact of casting must be addressed. As industries push for greener practices, the pressure is on to innovate responsibly. In this landscape, Tin Bronze Precision Casting stands at a crossroads, showcasing both potential and the need for reflection.

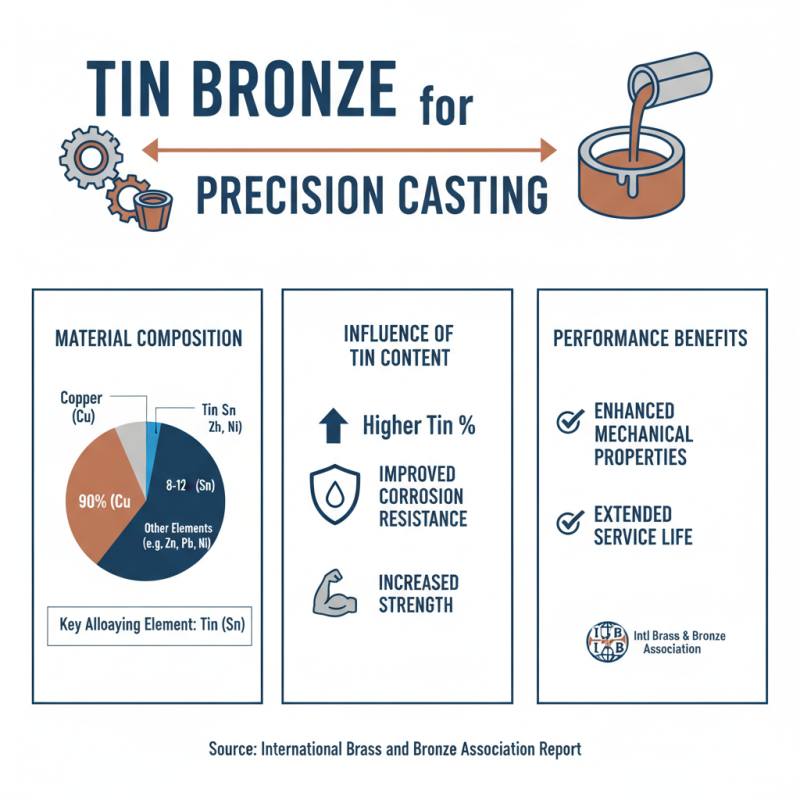

The trend of tin bronze for precision casting has seen significant developments. The material composition of tin bronze plays a vital role in determining its performance. Tin bronze typically consists of copper, tin, and small amounts of other elements. Recent studies indicate that tin content can influence mechanical properties. A report from the International Brass and Bronze Association indicates that higher tin percentages can improve corrosion resistance and strength.

Casting techniques have also evolved, incorporating advanced technologies. According to a recent industry analysis, the incorporation of additives like nickel and phosphorus can further enhance the properties of tin bronze. However, precision in the composition is critical. Over-alloying could lead to brittleness, a factor that needs careful consideration in casting processes. The challenge remains in balancing cost and performance, as higher alloying might increase production expenses.

As demand grows, we see emerging innovations in mold design and pouring techniques. Data shows efficiency improvements of up to 25% in certain casting processes. However, some issues persist. The variability in raw material quality can lead to inconsistencies in the final product. It's a constant reminder for the industry to refine quality control measures. Every development brings forth new challenges for manufacturers to address. Balancing innovation with reliability is key to the future of tin bronze casting.

The world of precision casting is evolving rapidly. New techniques are emerging, enhancing accuracy in tin bronze casting. These advancements are crucial for industries requiring intricate designs. For example, the use of 3D printing in mold creation allows for remarkable precision. This innovation enables manufacturers to achieve complex geometries effortlessly.

However, challenges remain. Achieving the perfect balance between speed and accuracy can be difficult. Sometimes, the materials used do not perform as expected. This can lead to defects in the final product. Continuous testing and refinement are essential. Manufacturers must consistently evaluate their processes to adapt to these hurdles.

Innovative approaches like laser sintering are also gaining traction. This technique can create parts with minimal waste. It's a more sustainable option, yet it requires skilled operators. The demand for precision casts means that training is vital. Without proper guidance, errors can crop up, highlighting the need for ongoing education in the industry.

The demand for sustainable practices in tin bronze precision casting is growing. In 2022, the global casting market size was valued at approximately $200 billion, with a significant shift towards eco-friendly methods. This trend is expected to influence techniques by 2026. Many manufacturers are exploring ways to minimize waste and energy consumption.

Recycling is gaining traction in this sector. Tin bronze can be recycled multiple times without losing its properties. According to recent industry reports, recycled metals can reduce energy usage by up to 95%. This is a crucial improvement, considering mining and refining new materials is resource-intensive. However, not all companies have adopted these practices. Some still rely heavily on virgin materials, raising questions about commitment to sustainability.

Innovations in technology play a role. Additive manufacturing, for example, allows for precise material use, minimizing scrap. Smart manufacturing processes can track energy consumption, leading to better decision-making. Yet, challenges remain. Not every facility has access to the latest technology. Some also lack proper training in sustainable practices. This gap in knowledge can hinder progress and needs addressing for a greener future in tin bronze precision casting.

| Trend | Description | Sustainability Impact | Innovation Level | Market Adoption |

|---|---|---|---|---|

| Recycled Materials | Increased use of recycled tin and bronze to minimize environmental impacts. | High | High | Growing |

| Energy-efficient Processes | Implementing processes that reduce energy consumption during casting. | Medium | Medium | Moderate |

| Automation and Smart Casting | Utilization of AI and automation technologies to enhance precision. | Low | High | Emerging |

| Biodegradable Casting Materials | Development of environmentally friendly materials for casting. | Very High | Medium | Limited |

| Enhanced Quality Control | Improved techniques for ensuring the quality and purity of the cast materials. | Medium | High | Widespread |

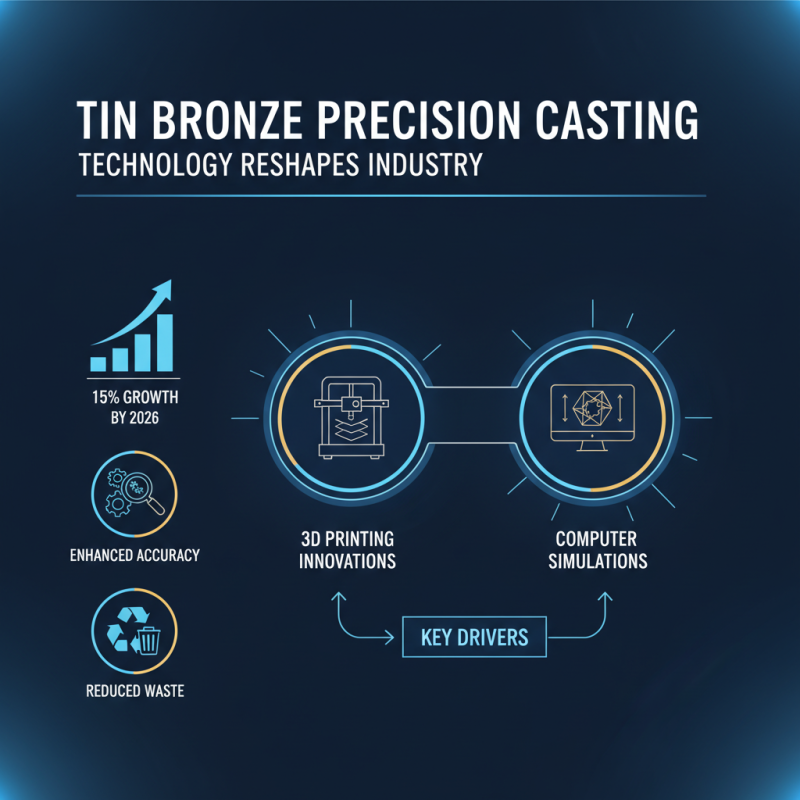

Emerging technologies in tin bronze precision casting are reshaping the industry. A recent report predicts a 15% growth in this sector by 2026. Innovations in 3D printing and computer simulations are leading the charge. These methods enhance accuracy, reducing waste significantly.

Precision casting techniques now rely on advanced materials and analytical tools. The use of simulation software allows engineers to predict the behavior of bronze during the casting process. By employing these technologies, companies can achieve a higher yield rate of up to 85%. However, the integration of these methods requires continuous training and adaptation. Not all firms may keep pace, leading to potential disparities in productivity.

Investments in robotic automation are also noteworthy. These systems minimize human error and optimize resource allocation. Despite these advancements, some challenges remain. The initial costs of adopting new technology can be prohibitive. There is also the risk of over-reliance on automation, which can stifle creativity in problem-solving. Balancing innovation with traditional skills may be crucial for sustainable growth in the tin bronze casting sector.

The future of tin bronze precision casting is poised for exciting developments. Innovations will focus on improving casting accuracy and reducing wastage. Manufacturers will likely adopt advanced technologies like 3D printing. This can enhance design complexity and allow rapid prototyping.

Customization is becoming crucial in various industries, pushing for tailored solutions.

Market projections reveal a steady demand for tin bronze components. These materials offer excellent corrosion resistance and wear properties. As industries seek durable solutions, tin bronze will gain more attention. Cost efficiency remains a challenge.

Companies need to balance innovation and budget constraints. A lack of skilled workers could hinder the adoption of new techniques. This raises questions about training and development.

Furthermore, environmental concerns are influencing casting processes. Sustainable practices will likely become a priority. The push for greener options may lead to unexpected challenges. For instance, sourcing eco-friendly materials can prove difficult. As the market evolves, staying adaptable will be key. Companies must remain vigilant to trends and customer feedback. This will foster a more inclusive and innovative environment.